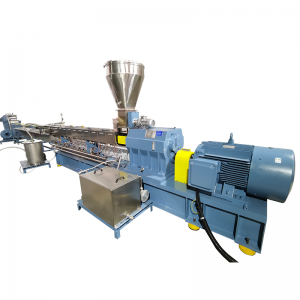

I-LB-WaterRing Cutting Granulating Line

| Imodeli | I-LBWR-80 | I-LBWR-100 | I-LBWR-140 | I-LBWR-160 | I-LBWR-180 |

| Isikulufa Imodeli | 80/38:1 | 100/38:1 | 140/38:1 | 160/38:1 | 180/38:1 |

| I- throughput(kg) | 120-160 | 260-400 | 450-600 | 600-800 | 800-1000 |

| Amandla Emotor(kW) | 55 | 110 | 200 | 250 | 315 |

I-Automatic Conveyor

I-AC Driver elawulwa yi-conveyor motor driven

Umtshina wensimbi njengokuzikhethela ulawula isenzo se-conveyor ngesixwayiso kanye nokumisa.

I-conveyor yokuphakelayo elawulwa isivinini sokuphakela i-AC Driver incike kumthamo wesikhathi sangempela we-compactor.

I-Compactor eyakhelwe ngaphakathi

I-Stator ne-rotor ukusika impahla eluhlaza.Ukungqubuzana kwezinsalela zezinto kwandisa izinga lokushisa ku-compactor.Izinga lokushisa eliphezulu lisiza i-material ekunciphiseni umswakama kanye nokuhlukaniswa kothuli nezinsalela zezinto ezibonakalayo.Idivayisi ye-Degassing idedela umswakama ku-compactor futhi inikeze okokusebenza ngesimo esingcono ukuze kuqhutshekwe nokucubungula

I-Extruder yesikulufu esisodwa

Isicelo sifakazele ukuhambisana kwesikulufa kanye nemoto ukuze kukhiqizwe okuzinzile kanye nesikhathi eside sesevisi.Ikhwalithi ephezulu yesikulufu kanye nokucutshungulwa kwe-Bi-metal ye-extrusion ephezulu esebenzayo nesikhathi eside sokusebenza.

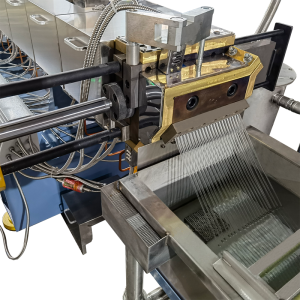

Isihlungi se-Hydraulic Melt Mold

Izikrini zensimbi ezingama-304 ezinosayizi wemeshi owenzelwe wena

Ipuleti le-Hydraulic noma umzimba wokuhlunga isilinda uyatholakala.

I-heater yethusi yokusebenza kahle kakhulu kokushisa

Isikrini esizenzakalelayo esigcwele sokushintsha isistimu ngokuzikhethela

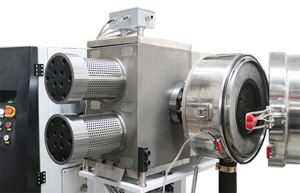

I-Water-Ring Granulator

Ingcindezi yokuxhumana phakathi kommese ojikelezayo nobuso bokufa igadwa isikhathi eside sokusika kanye nekhwalithi ephezulu yama-granules.Isivinini sokuzungezisa sommese sisekelwe ekuncibilikeni kokuncibilika futhi silungiswa ngokuzenzakalela.Idivayisi yommese ojikelezayo iyalungiseka ukuze ilungiswe.Ukushintshwa kalula kwemimese konga isikhathi ngokulungiswa.

Isisefo sokudlidliza

Imisebenzi emibili, Ukulawula Ukukhipha amanzi kanye Nosayizi, Yesihlungi Sokudlidliza:

Ngemuva kwe-water-ring granulating, ama-granules athuthwa emanzini.Ku-Vibration Sieve amanzi ayageleza futhi ama-granules ahlala esinyathelweni esengeziwe.

Usayizi wama-granules olawulwa ngesisefo sokudlidliza ama-granules amancane kakhulu noma amakhulu kakhulu azophenyiselwa ngaphandle.Okuwukuphela kwama-granules, alingana nemfuneko kasayizi azothuthelwa esiseleni sokugcina ngomoya.

Ukomisa System

Ukomisa ama-granules, umqondo wokomisa i-centrifuge kanye nowokuthutha umoya usetshenziswa.Ama-Granules azothuthwa ngomoya esiseleni sokugcina futhi umswakama wempahla uzoba ngaphansi kuka-1%.

ISilo Sokugcina

Ama-Granules wokugcina azogcinwa esiseleni.Ngokusekelwe kwisidingo uhlelo lokuqapha kanye nesisindo se-inthanethi lungasetshenziswa.