I-LB-WaterRing Cutting Granulating Line

| Imodeli | I-LBWR-80 | I-LBWR-100 | I-LBWR-140 | I-LBWR-160 | I-LBWR-180 |

| Isikulufa Imodeli | 80/38:1 | 100/38:1 | 140/38:1 | 160/38:1 | 180/38:1 |

| I- throughput(kg) | 120-160 | 260-400 | 450-600 | 600-800 | 800-1000 |

| Amandla Emotor(kW) | 55 | 110 | 200 | 250 | 315 |

I-Automatic Conveyor

I-AC Driver elawulwa yi-conveyor motor driven

Umtshina wensimbi njengokuzikhethela ulawula isenzo se-conveyor ngesixwayiso kanye nokumisa.

I-conveyor yokuphakelayo elawulwa isivinini sokuphakela i-AC Driver incike kumthamo wesikhathi sangempela we-compactor.

I-Compactor eyakhelwe ngaphakathi

I-Stator ne-rotor ukusika impahla eluhlaza. Ukungqubuzana kwezinsalela zezinto kwandisa izinga lokushisa ku-compactor. Izinga lokushisa eliphezulu lisiza i-material ekunciphiseni umswakama kanye nokuhlukaniswa kothuli nezinsalela zezinto ezibonakalayo. Idivayisi ye-Degassing idedela umswakama ku-compactor futhi inikeze okokusebenza ngesimo esingcono ukuze kuqhutshekwe nokucubungula

I-Extruder yesikulufu esisodwa

Isicelo sifakazele ukuhambisana kwesikulufa kanye nemoto ukuze kukhiqizwe okuzinzile kanye nesikhathi eside sesevisi. Ikhwalithi ephezulu yesikulufu kanye nokucutshungulwa kwe-Bi-metal ukuze kukhishwe ngempumelelo okuphezulu kanye nesikhathi eside sokusebenza.

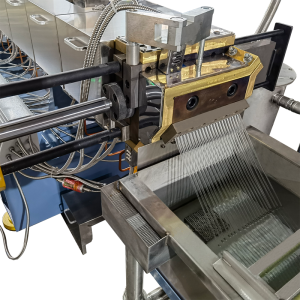

Isihlungi se-Hydraulic Melt Mold

Izikrini zensimbi ezingama-304 ezinosayizi wemeshi owenzelwe wena

Ipuleti le-Hydraulic noma umzimba wokuhlunga isilinda uyatholakala.

I-heater yethusi yokusebenza kahle kakhulu kokushisa

Isikrini esizenzakalelayo esigcwele sokushintsha isistimu ngokuzikhethela

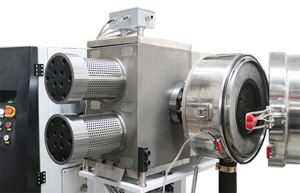

I-Water-Ring Granulator

Ingcindezi yokuxhumana phakathi kommese ojikelezayo nobuso bokufa igadwa isikhathi eside sokusika kanye nekhwalithi ephezulu yama-granules. Isivinini sokuzungezisa sommese sisekelwe ekuncibilikeni kokuncibilika futhi silungiswa ngokuzenzakalela. Idivayisi yommese ojikelezayo iyalungiseka ukuze ilungiswe. Ukushintshwa kalula kwemimese konga isikhathi ngokulungiswa.

Isisefo sokudlidliza

Imisebenzi emibili, Ukulawula Ukukhipha amanzi kanye Nosayizi, Yesihlungi Sokudlidliza:

Ngemuva kwe-water-ring granulating, ama-granules athuthwa emanzini. Ku-Vibration Sieve amanzi ayageleza futhi ama-granules ahlala esinyathelweni esengeziwe.

Usayizi wama-granules olawulwa ngesisefo sokudlidliza ama-granules amancane kakhulu noma amakhulu kakhulu azophenyiselwa ngaphandle. Okuwukuphela kwama-granules, alingana nemfuneko kasayizi azothuthelwa esiseleni sokugcina ngomoya.

Ukomisa System

Ukomisa ama-granules, umqondo wokomisa i-centrifuge kanye nowokuthutha umoya usetshenziswa. Ama-Granules azothuthwa ngomoya esiseleni sokugcina futhi umswakama wempahla uzoba ngaphansi kuka-1%.

ISilo Sokugcina

Ama-Granules wokugcina azogcinwa esiseleni. Ngokusekelwe kwisidingo uhlelo lokuqapha kanye nesisindo se-inthanethi lungasetshenziswa.