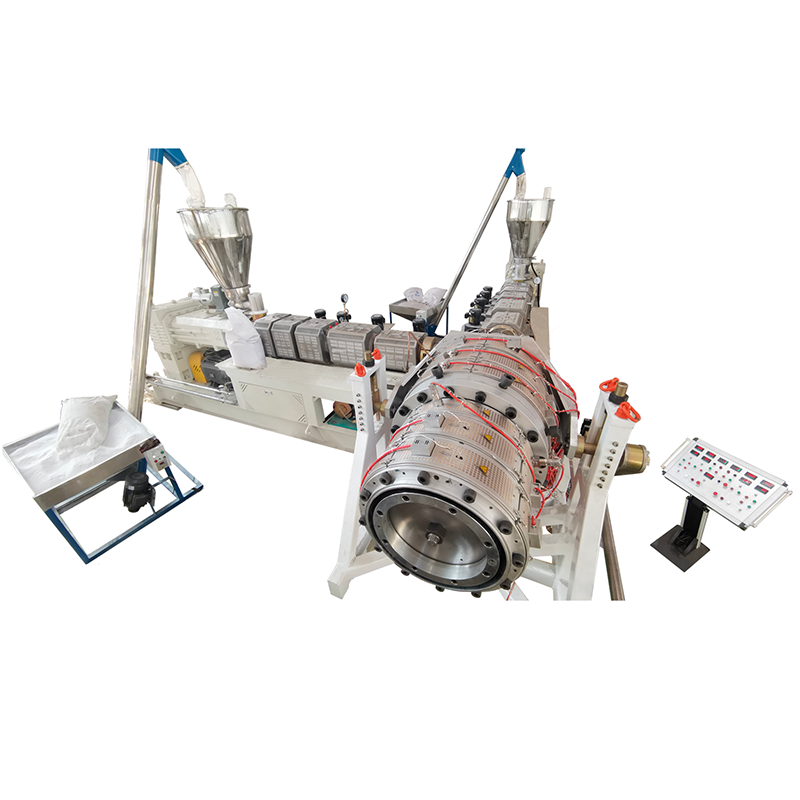

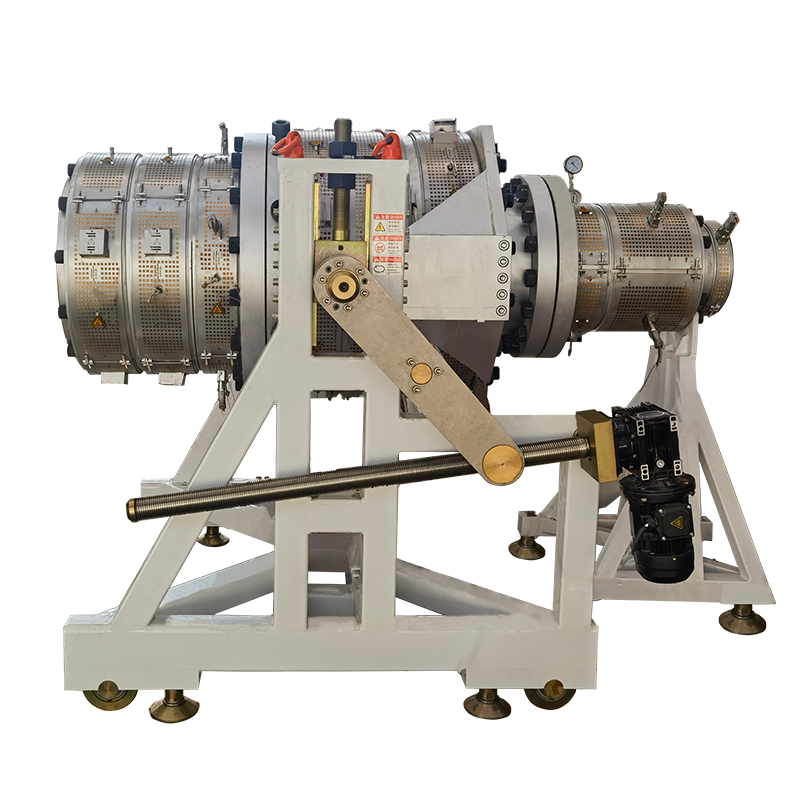

LB-PVC Umugqa Omkhulu Wokunwetshwa Kwepayipi Lobubanzi

I-PVC powder + isithako — ukuxuba—isiphakeli sezinto—isikhunta nesikhunta—umshini wokwenza ivacuum—umshini wokupholisa wokufafaza—umshini wokudonsa—umshini wokusika—irack yokukhipha noma umshini wokubethela ipayipi.

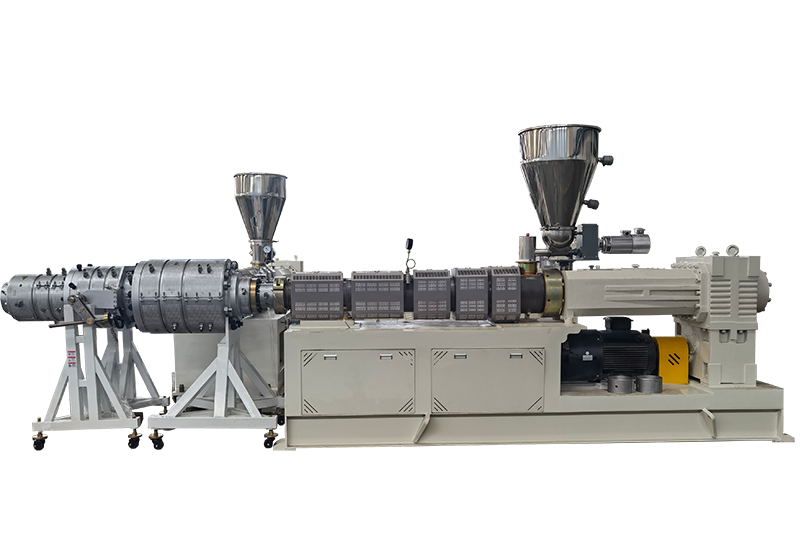

| Imodeli | 630 | 800 | 1000 |

| Ibanga lamapayipi (mm) | 315-630 | 560-800 | 630-1000 |

| Isikulufa Imodeli | 80/156 | 92/188 | 92/188 |

| I- throughput(kg) | 350 | 800 | 1100 |

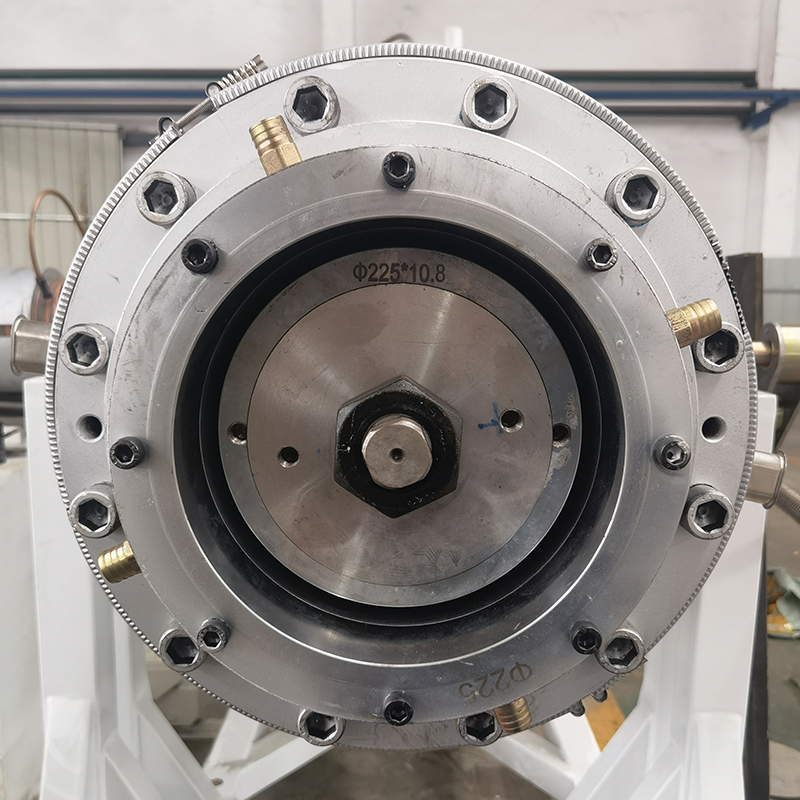

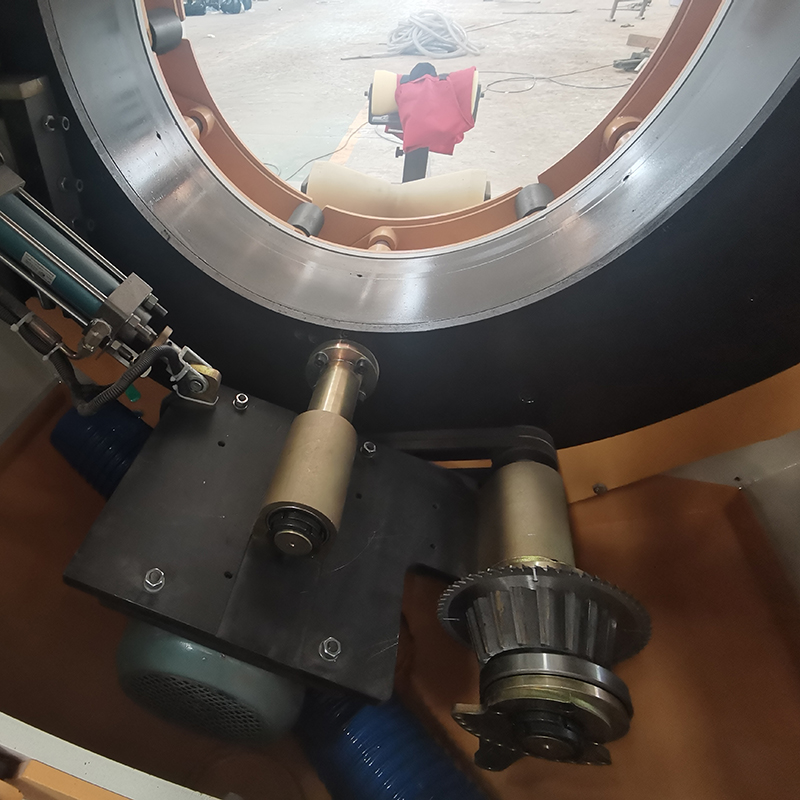

I-Conical Twin Screw Extruder

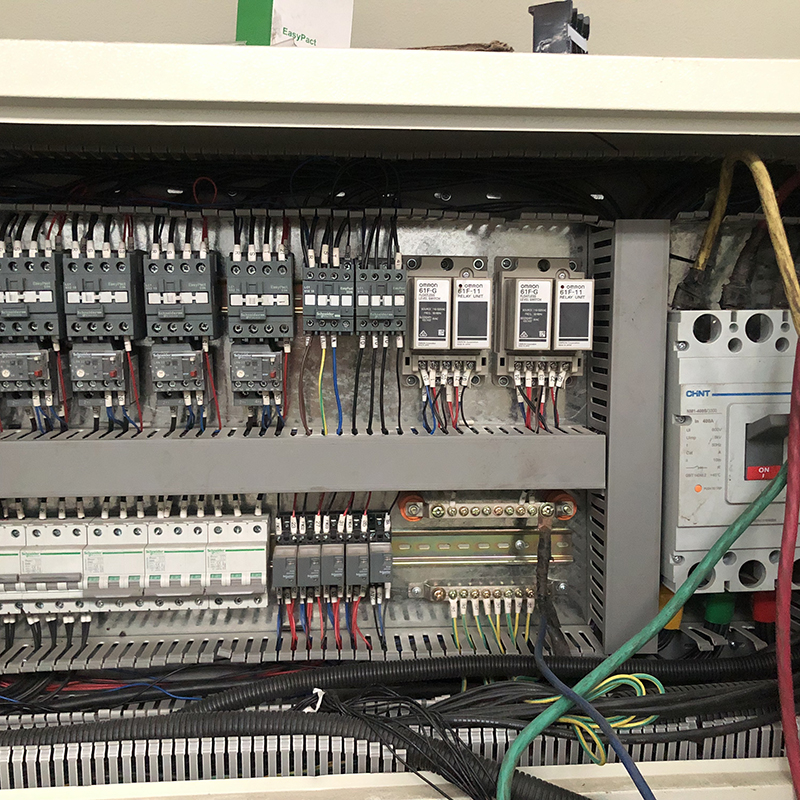

Samukela i-Siemens motor nesivinini esilawulwa yi-inverter ye-ABB. Uhlelo lokulawula lusebenzisa ukulawula kwe-Siemens PLC noma ukulawula izinkinobho. I-conical twin screw extruder yolayini wepayipi isebenzisa isikulufu nomgqomo osebenza kahle kakhulu, i-gearbox enesistimu yokuzithambisa. With touch screen (uyazikhethela) ohlakaniphe kakhudlwana futhi operation lula.

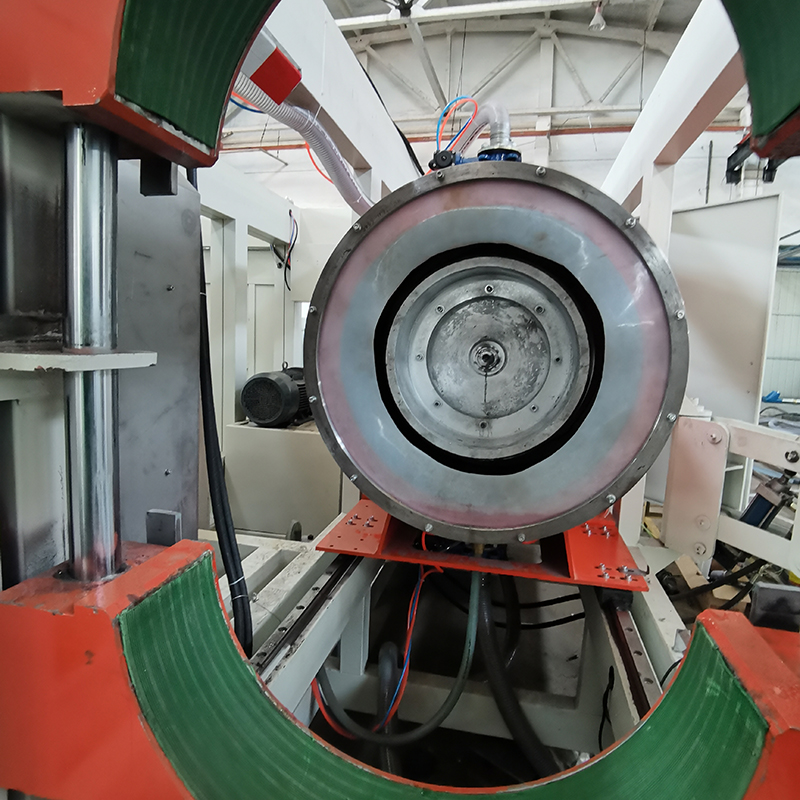

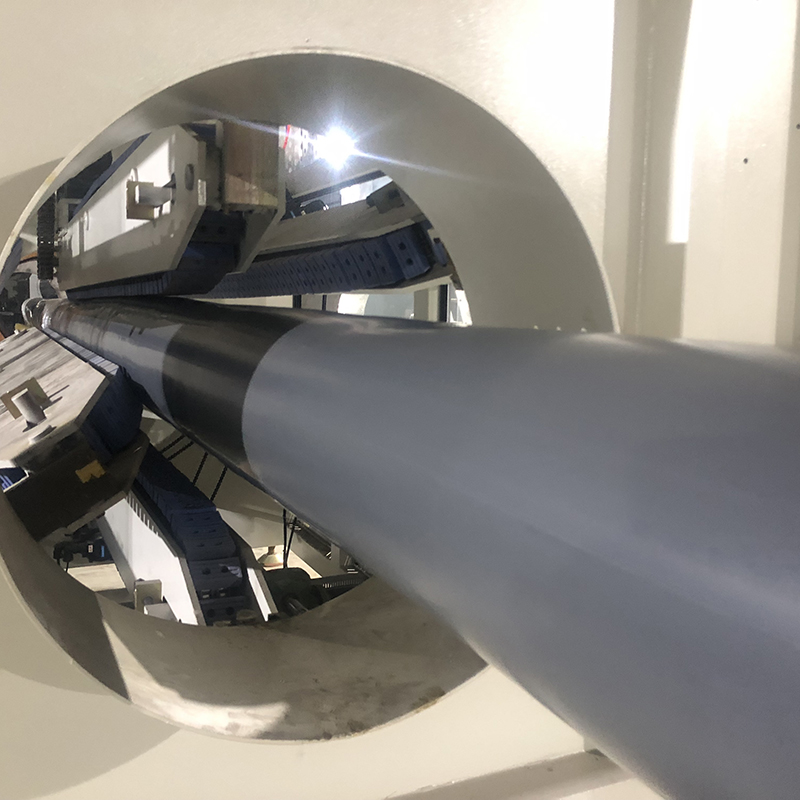

Isikhunta

Isikhunta sinomklamo obanzi wesiteshi sokugeleza ukuze kuqinisekiswe umthamo ophezulu wokukhipha kanye nomthelela omuhle wokuncibilika.

Yenziwa futhi ihlolwe ngumkhiqizi onolwazi. Ukulawulwa kwezinga lokushisa okuthuthukisiwe kanye nomklamo wesiteshi sokugeleza kuqinisekisa ukulawulwa okunembile kwezinga lokushisa lokuncibilika.

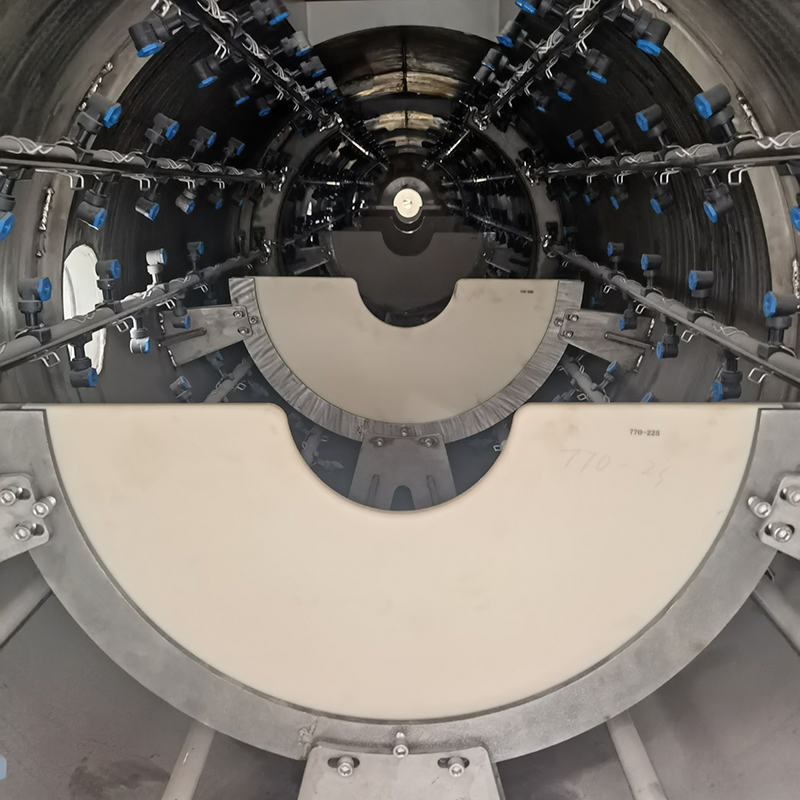

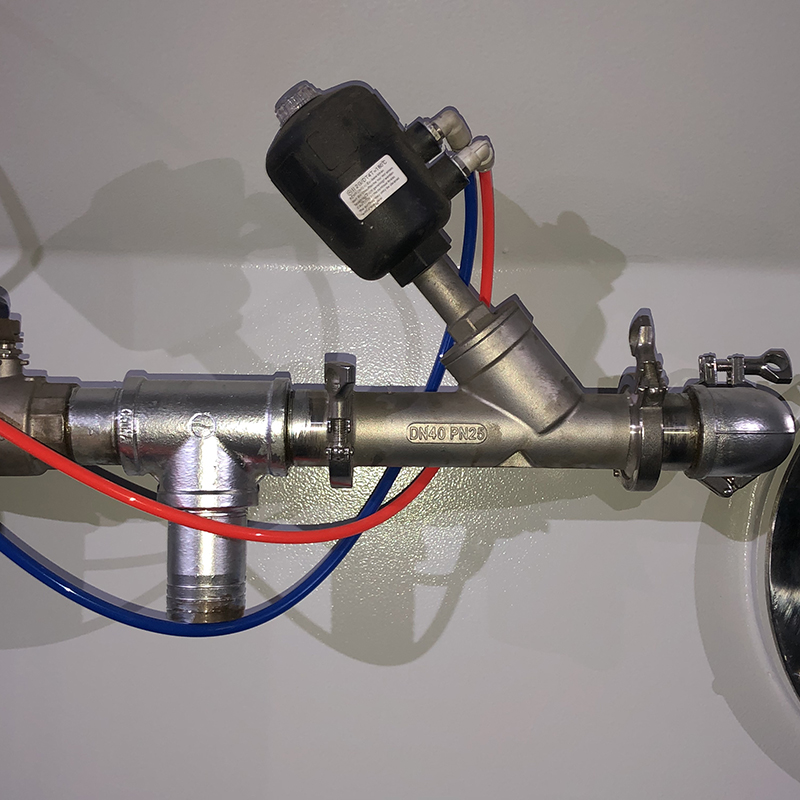

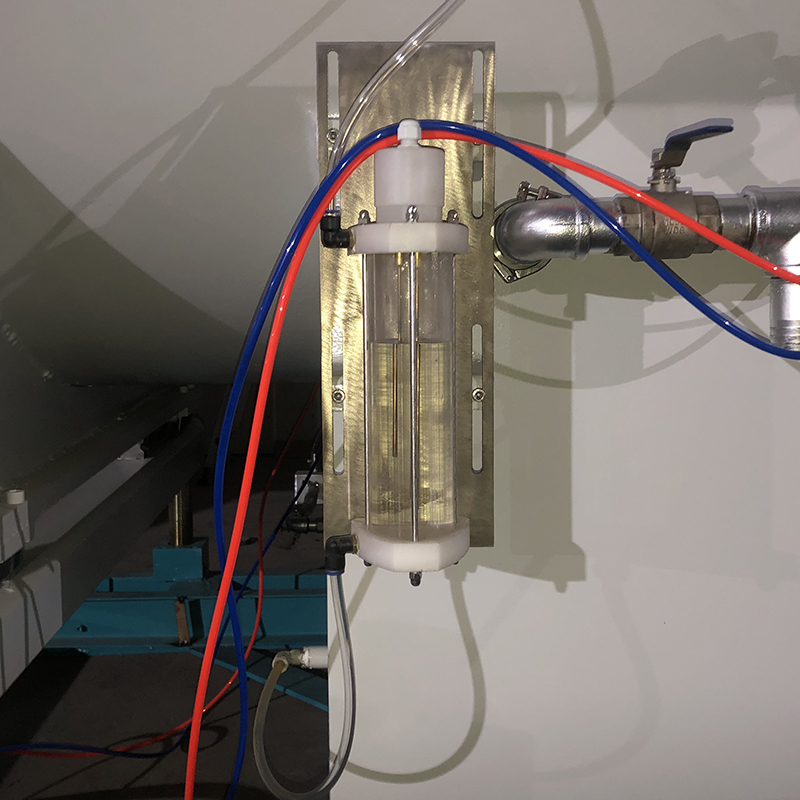

Iyunithi Yokulinganisa Nokupholisa Ivacuum

Kokubili ithangi le-vacuum nethangi lokupholisa lokufafaza lisebenzisa insimbi engagqwali engu-304. Ngobude obanele bokuchela nokupholisa kuzothuthukisa ukusebenza kahle kokupholisa; Isistimu yokulawula izinga lokushisa lamanzi ngokuzenzakalelayo ilungiswa ngokuya ngokuzwa kwezinga lokushisa.

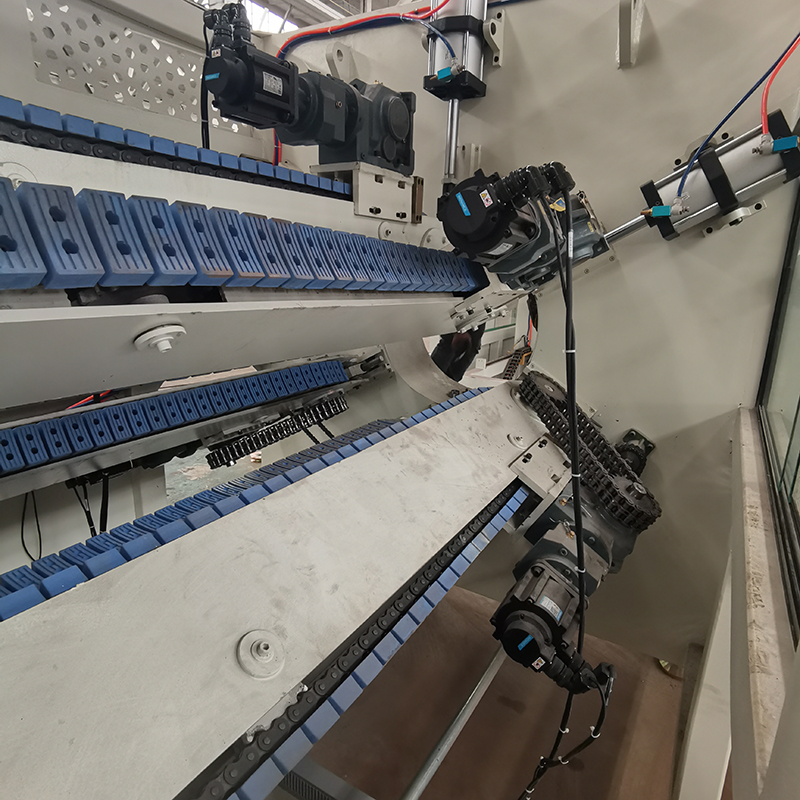

Umshini Wokukhipha

Isibungu esiyisithupha emshinini wokudonsa siqinisekisa ukuthi amapayipi akhiqiziwe asebenza ngokuzinzile futhi azinzile. Amayunithi okudonsa angenza imodeli yokudonsa ehambisanayo ngokususelwe kumfuneko ethile yokukhiqiza ngokulungisa isilawuli esijwayelekile.

Umsiki

Isifaki khodi sokunemba okuphezulu siqinisekisa ubude bokusika obunemba futhi obuzinzile. Ngesistimu yokulawula ye-PLC, ingasikwa ngokusebenza ngesandla ngokuya ngohlelo oluthile.

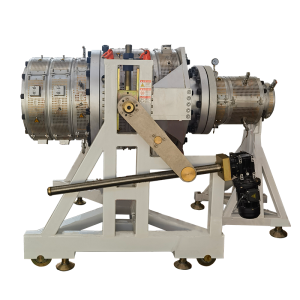

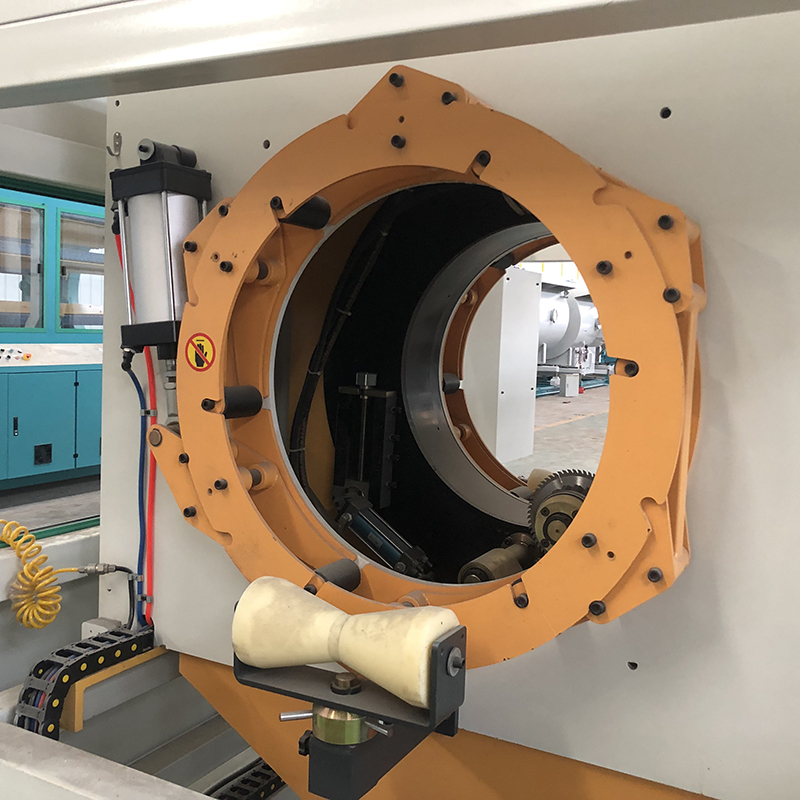

Umshini wezinsimbi

Ulayini unesistimu ye-socketing ye-inthanethi ezenzakalelayo esebenza ngokuzinzile nangobuhlakani. Ukushisisa nokupholisa kwayo kusebenza kahle kakhulu futhi kunembe. Isokhethi yepayipi iyindilinga futhi ibushelelezi. Inikeza indawo yokushisa emibili yokushaya ngesikhathi ngesivinini somugqa.