I-LB-PP/PE Umugqa Womshini Wokusika Ngaphansi Wamanzi Wokusika

| Imodeli | I-LBUW-40 | I-LBUW-50 | I-LBUW-60 | I-LBUW-70 | I-LBUW-80 | I-LBUW-90 |

| Isikulufa Imodeli | 41/24-80:1 | 52/24-80:1 | 62/24-80:1 | 71/24-80:1 | 81/24-80:1 | 93/24-80:1 |

| I- throughput(kg) | 130 | 250 | 400 | 500 | 800 | 1000 |

| Amandla Emotor(kW) | 37 | 75 | 110 | 160 | 250 | 315 |

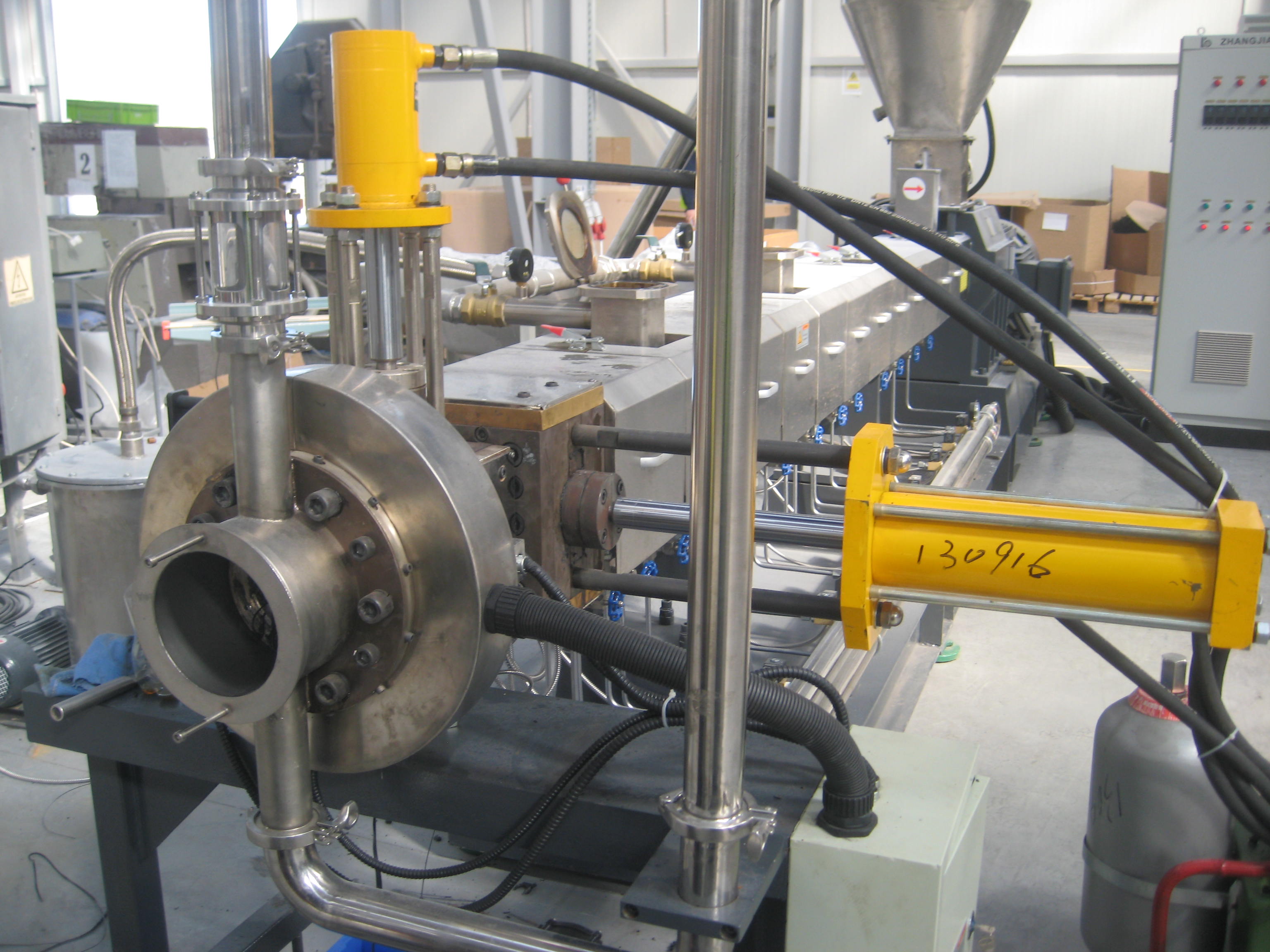

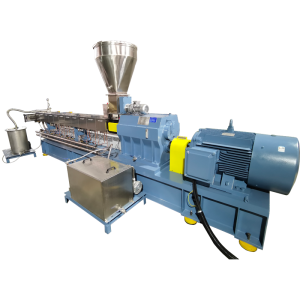

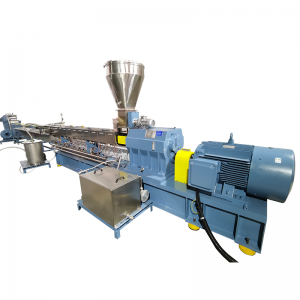

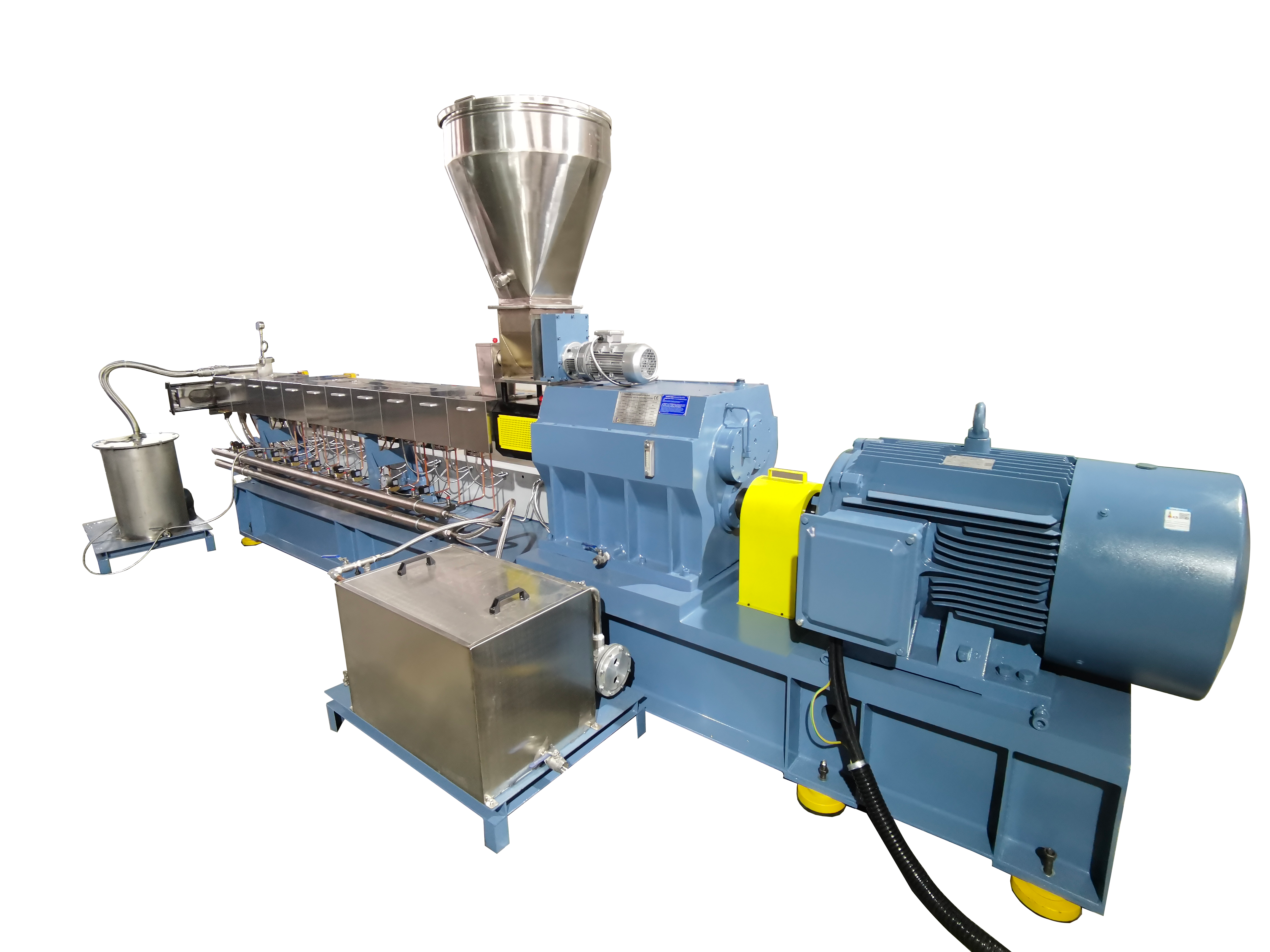

I-Parallel Twin Screw Extruder

Ngokusekelwe ohlelweni lokukhiqiza olwenziwe ngezifiso sinemiqondo ehlukene ye-extrusion esingakhetha ngayo. I-Parallel Twin Screw Extruder isekelwe kulwazi lwethu olusetshenziswa kakhulu kwisisombululo se-extrusion, esihlangana nedivayisi yokuhlanganisa engaphansi kwamanzi.

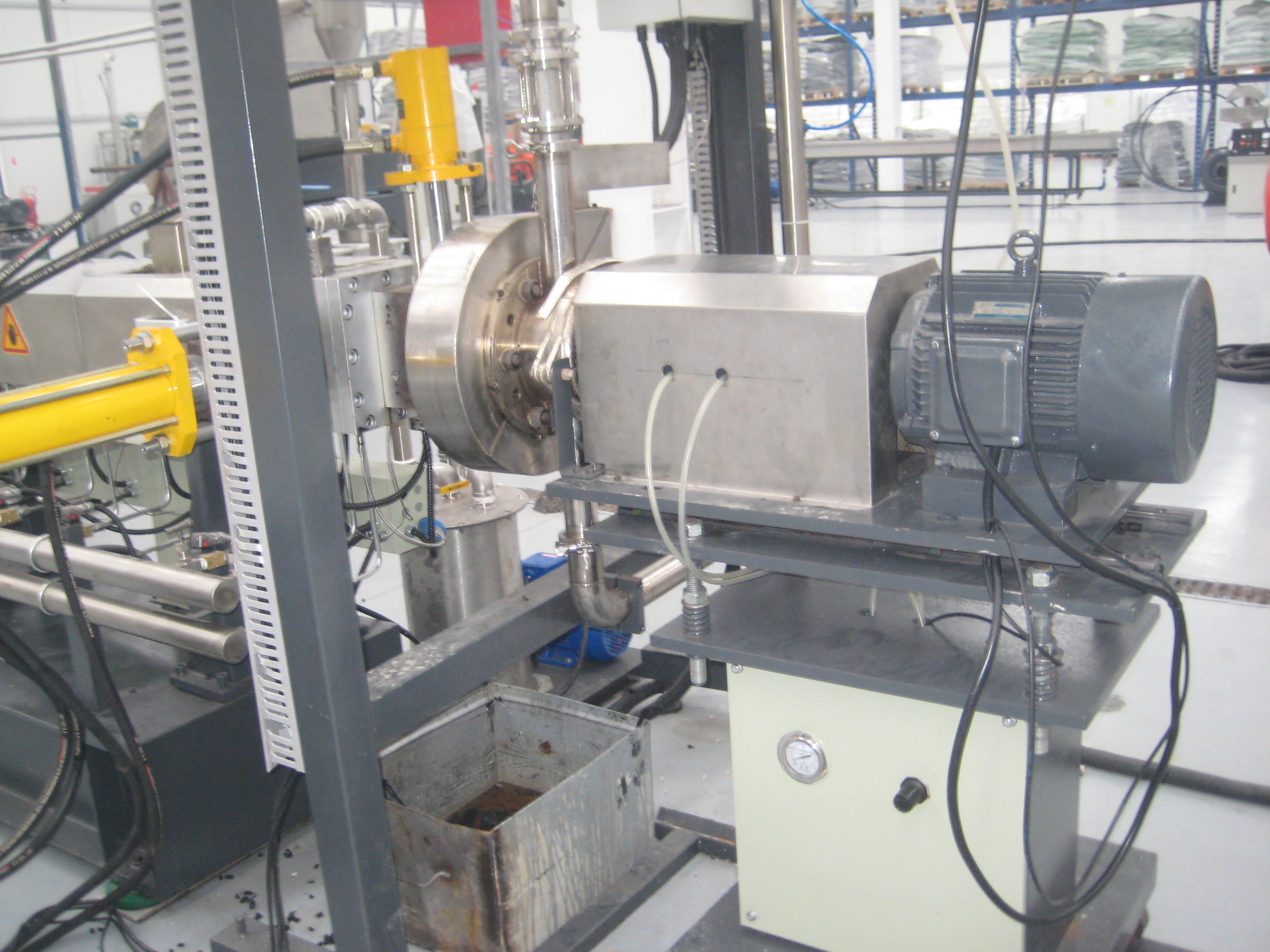

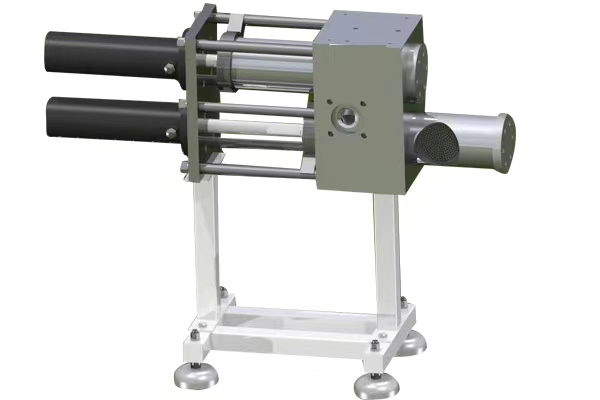

Ukushintsha isikrini

Ukushintsha isikrini kusetshenziselwa ukuhlanza ukungcola ekuncibilikeni (isihlabathi, insimbi, amapulasitiki ahlukene) okunciphisa ikhwalithi yegranule. Kunezinhlobo ezahlukene zokushintsha isikrini okufana nokushintsha isikrini sepuleti elilodwa noma esikabili kanye nokushintsha isikrini okukodwa noma okuyisilinda esikabili. Ngokusekelwe ezimweni ezihlukene zokusebenza kuzothathwa isishintshi sesikrini esifanele.

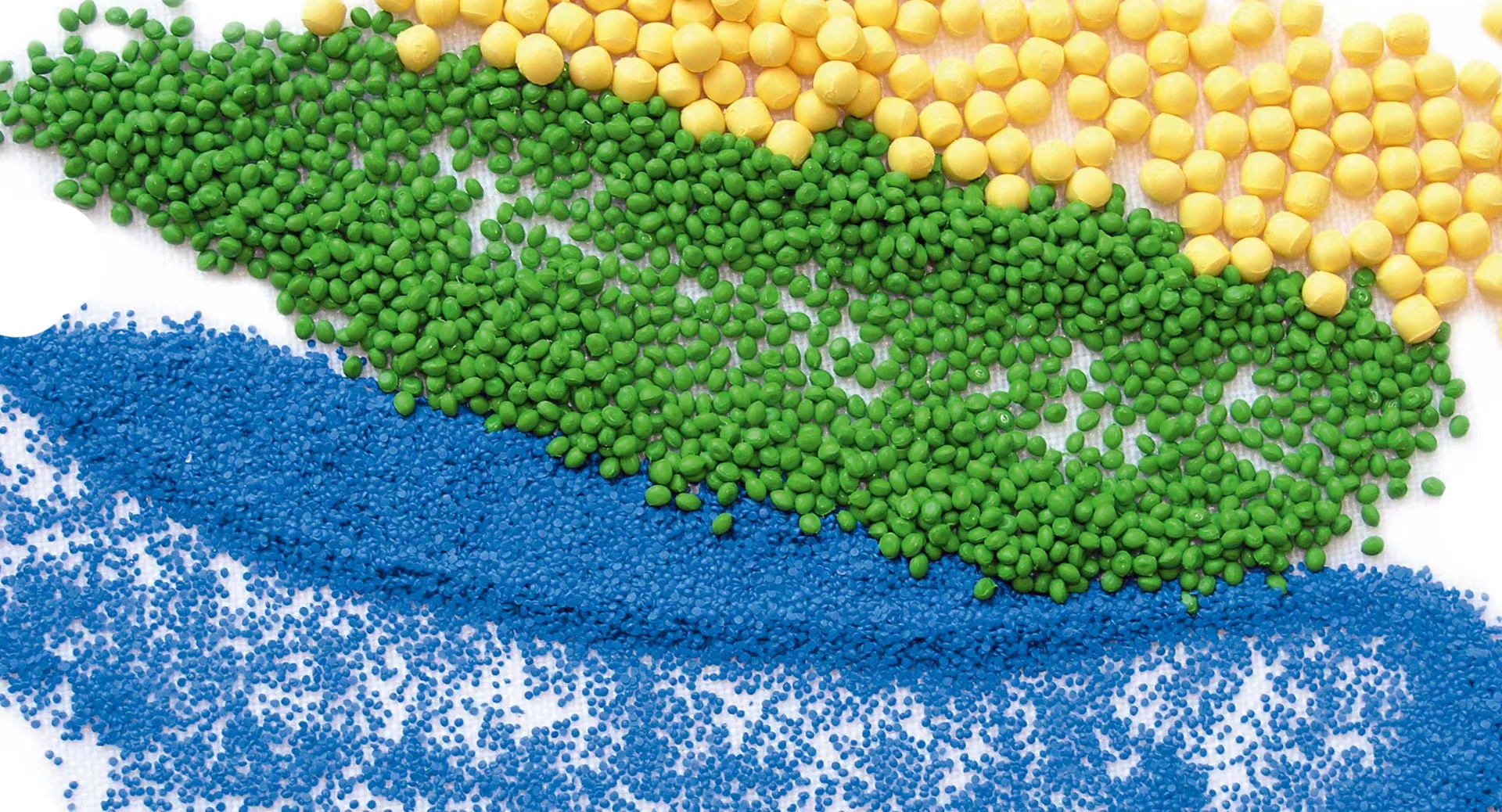

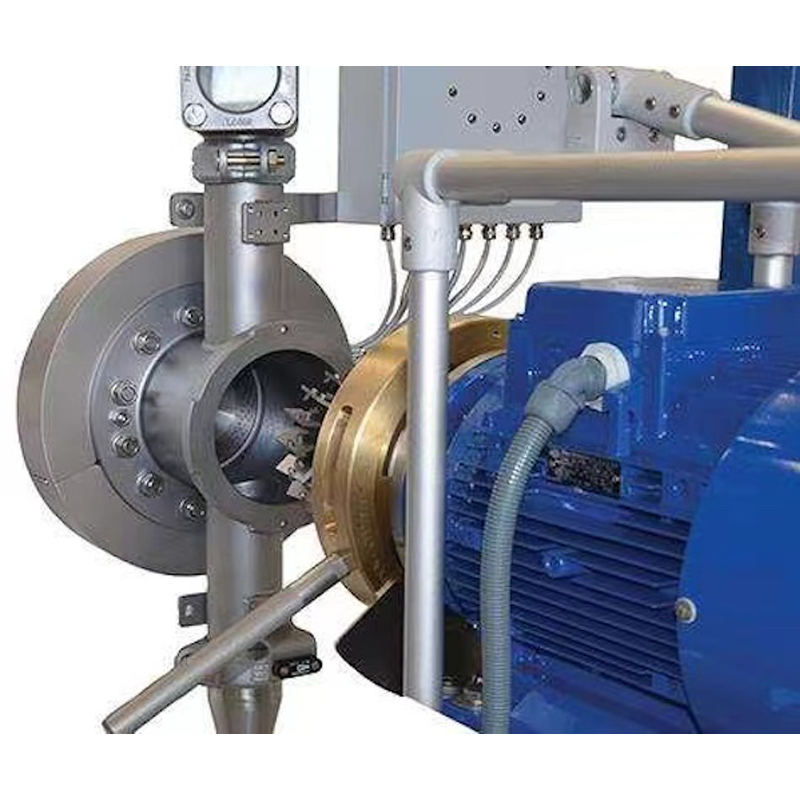

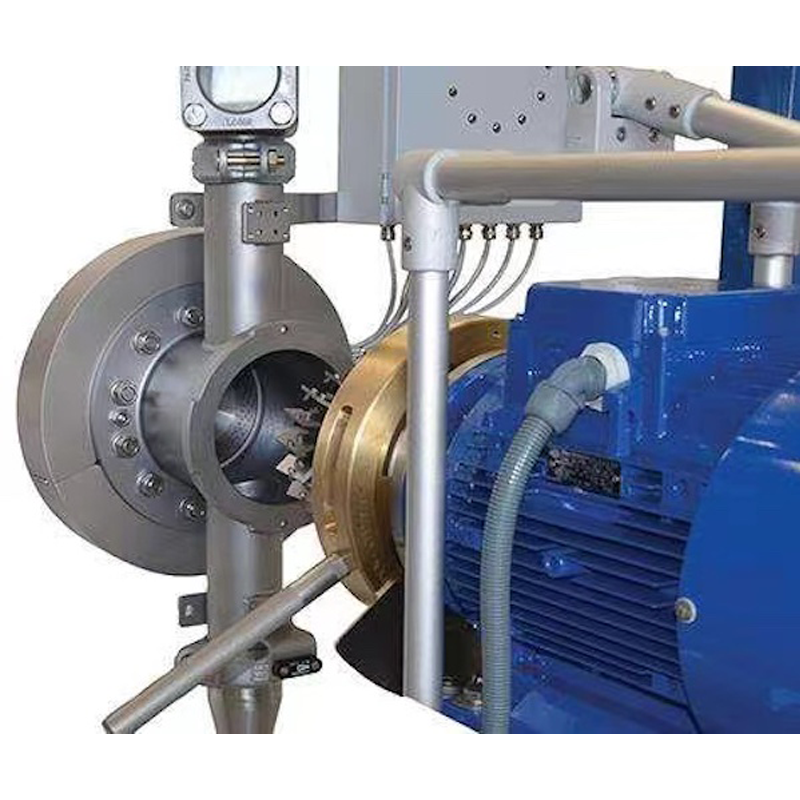

Isistimu ye-Granulating engaphansi kwamanzi

Qhubekaukucindezela kwesenzo phakathi kommese ojikelezayo kanye nobuso bokufa kubhekwa isikhathi eside sokusika kanye nekhwalithi ephezulu yama-granules. Isivinini sokuzungezisa sommese sisekelwe ekuncibilikeni kokuncibilika futhi silungiswa ngokuzenzakalela. Idivayisi yommese ojikelezayo iyalungiseka ukuze ilungiswe. Ukushintshwa kalula kwemimese konga isikhathi ngokulungiswa.

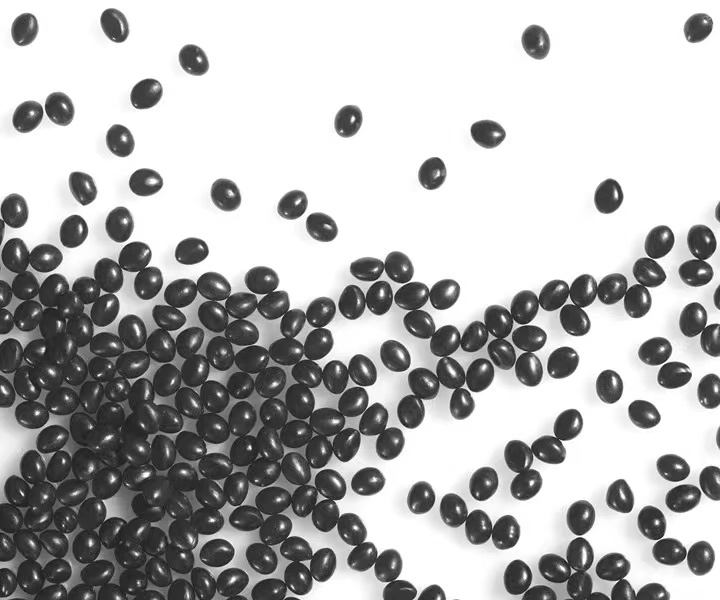

Ukukhipha amanzi e-Centrifugal

Ihlukanisa ama-granules namanzi. Ama-Granules azothuthwa ngokumiswa okumaphakathi ukusuka phansi kuye phezulu kudivayisi yokukhipha amanzi. Ngesikhathi sokuphakamisa umswakama uzoncishiswa ngokuphumelelayo.

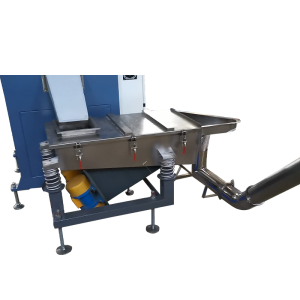

Visisefo se-ibration

TIsisefo sokudlidliza sihluza ama-granules ngosayizi wawo. Ama-granules amakhulu kakhulu noma amancane azohlungwa. Usayizi olungile kuphela ozothuthwa ku-silo yokugcina.

ISilo Sokugcina

Ama-Granules wokugcina azogcinwa esiseleni. Ngokusekelwe kwisidingo uhlelo lokuqapha kanye nesisindo se-inthanethi lungasetshenziswa.