Isigaba somgqomo womshini wokuvula

Eminye imiklamo yemiphongolo inikeza ukucushwa okuyingqayizivele kwama-twin screw extruder. Uma sibhangqa umphongolo ngamunye nokucushwa kwesikulufa esifanele, sizokwenza ucwaningo olujwayelekile nolujule kakhulu lwalolu hlobo lombhobho ngamunye ngokusebenza kweyunithi kuleyo ngxenye ye-extruder.

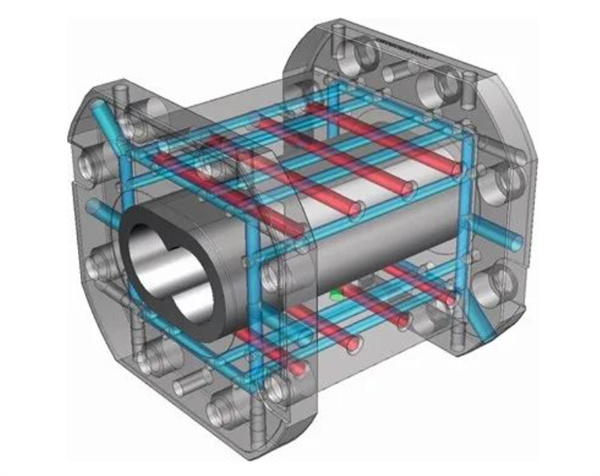

Isigaba ngasinye semiphongolo sineshaneli emise okwe-8 lapho i-screw shaft idlula khona. Umphongolo ovulekile unemigudu yangaphandle yokuvumela ukuphakela noma ukukhipha izinto eziguquguqukayo. Le miklamo evulekile yemigqomo ingasetshenziselwa ukuphakela nokukhipha umoya, futhi ingafakwa noma kuphi kuyo yonke inhlanganisela yomgqomo.

Okuphakelayo

Ngokusobala, impahla kufanele ifakwe ku-extruder ukuze iqale ukuxuba. Umgqomo wokuphakela uwumgqomo ovulekile oklanyelwe ukuba nembobo phezulu komgqomo okuphakelwa ngawo izinto. Indawo ejwayeleke kakhulu yesigubhu sokuphakelayo isendaweni engu-1, okuwumphongolo wokuqala esigabeni senqubo. Izinto eziwumbudumbudu kanye nezinhlayiya ezigeleza ngokukhululekile zikalwa kusetshenziswa okokuphakelayo, okuzivumela ukuthi ziwele ngokuqondile ku-extruder ngombhobho wokuphakelayo futhi zifinyelele isikulufu.

Ama-powders ane-low stacking density ngokuvamile abangela izinselele njengoba umoya uvame ukuthwala impushana ewayo. Lomoya ophunyukayo uvimba ukugeleza kwempushana ekhanyayo, wehlise ikhono lempushana ukondla ngezinga elidingekayo.

Enye inketho yokuphakela impushana ukusetha imiphongolo emibili evulekile emiphongolweni emibili yokuqala ye-extruder. Kulesi silungiselelo, i-powder ifakwa emgqonyeni wesi-2, okuvumela umoya ohlanganisiwe ukuthi ukhishwe emgqonyeni 1. Lokhu kulungiselelwa kubizwa ngokuthi idivayisi yokukhipha ngemuva. Imbobo engemuva ihlinzeka ngeshaneli ukuze umoya uphume ku-extruder ngaphandle kokuvimbela i-chute yokuphakelayo. Ngokususwa komoya, i-powder ingadliwa ngokuphumelelayo.

Uma i-polymer kanye nezithasiselo kufakwa ku-extruder, lezi zinsimbi zihanjiswa endaweni encibilikayo, lapho i-polymer incibilika futhi ihlanganiswe nezithasiselo. Izithasiselo zingaphakelwa phansi nomfula endaweni encibilika kusetshenziswa iziphakeli eziseceleni.

Qeda

Ingxenye ye-tube evulekile ingasetshenziselwa ukukhipha; Umhwamuko oguquguqukayo okhiqizwe ngesikhathi senqubo yokuhlanganisa kumele ukhululwe ngaphambi kokuba i-polymer idlule kufa.

Indawo esobala kakhulu yembobo ye-vacuum ibheke ekupheleni kwe-extruder. Lesi sizinda se-exhaust ngokuvamile sixhunywa kupompo ye-vacuum ukuze kuqinisekiswe ukuthi zonke izinto eziguquguqukayo ezifakwe ku-polymer melt ziyasuswa ngaphambi kokudlula ekhanda lesikhunta. Isitimu esisele noma igesi ekuncibilikeni kungaholela kukhwalithi yezinhlayiyana ezimbi, okuhlanganisa ukukhihliza amagwebu nokuncipha kokuminyana kokupakisha, okungase kuthinte umphumela wokupakisha wezinhlayiya.

Isigaba somgqomo esivaliwe

Umklamo ovame kakhulu we-cross-sectional we-barrel umgqomo ovaliwe. Ingxenye yomgqomo isonga ngokuphelele ukuncibilika kwe-polymer kuzo zonke izinhlangothi ezine ze-extruder, ngokuvuleka okukodwa okumise okwe-8 okuvumela isikhungo sesikulufu ukuthi sidlule.

Uma i-polymer kanye nanoma yiziphi ezinye izithasiselo sezifakwe ngokugcwele ku-extruder, impahla izodlula esigabeni sokudlulisa, i-polymer izoncibilika, futhi zonke izithasiselo nama-polymers zizohlanganiswa. Umgqomo ovaliwe unikeza ukulawula izinga lokushisa kuzo zonke izinhlangothi ze-extruder, kuyilapho umgqomo ovulekile unama-heaters ambalwa namashaneli okupholisa.

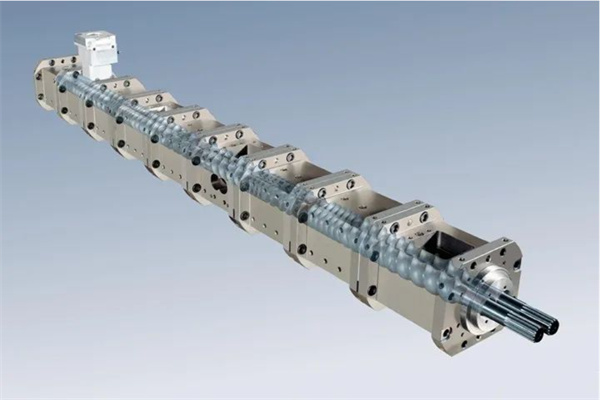

Ukuhlanganisa umgqomo we-extruder

Ngokuvamile, i-extruder izohlanganiswa ngumkhiqizi, ngesakhiwo somphongolo esifana nokucushwa kwenqubo edingekayo. Ezinhlelweni eziningi zokuxuba, i-extruder inomphongolo wokudla ovulekile emgqonyeni wokuphakela 1. Ngemva kwalesi sigaba sokudla, kunemiphongolo eminingana evaliwe esetshenziselwa ukuthutha okuqinile, ukuncibilikisa ama-polymers, nokuhlanganisa ama-polymer ancibilikisiwe kanye nezithasiselo ndawonye.

Isilinda esihlanganisiwe singatholakala kusilinda 4 noma 5 ukuvumela ukuphakelwa okuhlangene kwezithasiselo, kulandelwe amasilinda ambalwa avaliwe ukuze uqhubeke nokuxuba. Imbobo ye-vacuum exhaust itholakala ngasekugcineni kwe-extruder, ilandelwa eduze umgqomo wokugcina ovaliwe phambi kwekhanda lokufa. Isibonelo sokuhlanganisa umgqomo singabonakala kuMfanekiso 3.

Ubude be-extruder ngokuvamile buvezwa njengesilinganiso sobude nobubanzi besikulufu (L/D). Ngale ndlela, ukukhuliswa kwesigaba senqubo kuzoba lula, njengoba i-extruder encane enesilinganiso se-L / D se-40: 1 ingakhuliswa ibe yi-extruder enobubanzi obukhulu kanye nobude be-L / D be-40: 1.

Isikhathi sokuthumela: Apr-04-2023