1. Ijubane lokukrufula

Esikhathini esedlule, indlela eyinhloko yokwandisa ukukhishwa kwe-extruder kwakuwukwandisa ububanzi besikulufu. Nakuba ukwanda kobubanzi besikulufa kuzonyusa inani lempahla ekhishwe ngesikhathi seyunithi ngayinye. Kodwa i-extruder ayisona i-screw conveyor. Ngaphezu kokukhipha impahla, isikulufu siphinde sikhiphe, sixube futhi sishele ipulasitiki ukuze siyifake ipulasitiki. Ngaphansi kwesisekelo sesivinini esingaguquki sesikulufu, umthelela wokuhlanganisa nokugunda we-screw esinobubanzi obukhulu kanye ne-screw groove entweni ayilungile njengaleyo yesikulufu esinobubanzi obuncane. Ngakho-ke, ama-extruder anamuhla akhulisa kakhulu umthamo ngokwandisa isivinini se-screw. Isivinini sesikulufu se-extruder evamile singu-60 ukuya ku-90 rpm kuma-extruder endabuko. Futhi manje ngokuvamile seyenyusiwe yaba ngu-100 kuya ku-120 rpm. Ama-extruder esivinini esiphezulu afinyelela ku-150 kuya ku-180 rpm.

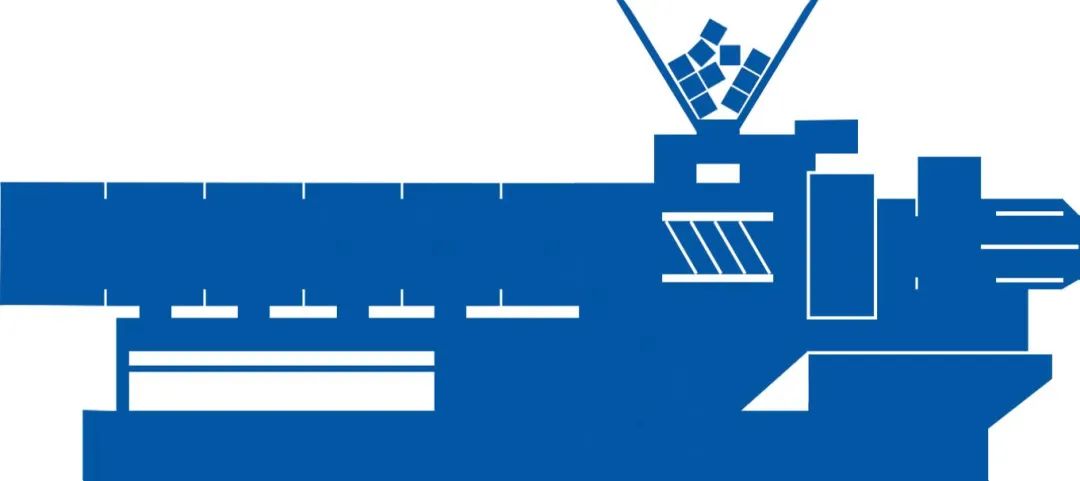

2. Isakhiwo sesikulufu

Isakhiwo sesikulufa yisici esiyinhloko esithinta umthamo we-extruder. Ngaphandle kwesakhiwo sesikulufu esiphusile, ukuzama ukuvele ukhuphule isivinini sesikulufu ukuze ukhuphule umthamo wokukhipha kuphambene nomthetho wenhloso futhi ngeke kuphumelele. Idizayini yesikulufu sejubane eliphezulu kanye nokusebenza kahle okuphezulu kususelwa kujubane eliphezulu lokuzungeza. Umphumela we-plasticizing walolu hlobo lwe-screw uzoba mpofu ngesivinini esiphansi, kodwa umphumela we-plasticizing uzothuthuka kancane kancane lapho isivinini se-screw sikhuphuka, futhi umphumela omuhle kakhulu uzotholakala lapho isivinini sokuklama sifinyelelwa. Kuleli qophelo, kokubili umthamo ophakeme kanye nemiphumela ye-plasticizing efanelekayo ifinyelelwa.

3. Ibhokisi lomshini

Izindleko zokukhiqiza isinciphisi zicishe zilingane nosayizi nesisindo saso, inqobo nje uma isakhiwo sifana ngokuyisisekelo. Ubukhulu nesisindo sika-gearbox sisho ukuthi kusetshenziswa izinto eziningi ngesikhathi sokukhiqiza kanti nama-bearings asetshenziswayo makhudlwana, okwandisa izindleko zokukhiqiza. Mayelana nokuphuma kweyunithi, amandla emoto aphansi kanye nesisindo esiphansi se-gearbox ye-extruder enesivinini esiphezulu sisho ukuthi izindleko zokukhiqiza ngeyunithi ngayinye okukhiphayo kwe-extruder enesivinini esiphezulu ziphansi kune-extruder evamile.

4. Ukushayela imoto

Ku-extruder ye-screw diameter efanayo, i-extruder ephezulu kanye nokusebenza kahle okuphezulu kudla amandla amaningi kune-extruder evamile, ngakho-ke kuyadingeka ukwandisa amandla emoto. Ngesikhathi sokusetshenziswa okuvamile kwe-extruder, isistimu ye-motor drive kanye nesistimu yokufudumeza nokupholisa ihlala isebenza. I-scruder ye-screw diameter efanayo ene-motor enkulu ibonakala ilambile amandla, kodwa uma ibalwa ngokuphumayo, i-extruder yesivinini esikhulu kanye nokusebenza kahle okuphezulu konga amandla kune-extruder evamile.

5. Izinyathelo zokudambisa ukudlidliza

Ama-extruder anesivinini esiphezulu athambekele ekudlidlizeni, futhi ukudlidliza ngokweqile kuyingozi kakhulu ekusebenziseni okuvamile kwemishini kanye nempilo yesevisi yezingxenye. Ngakho-ke, izinyathelo eziningi kufanele zithathwe ukunciphisa ukudlidliza kwe-extruder ukuze kwandiswe impilo yesevisi yemishini.

6. Izinsimbi

Ukusebenza kokukhiqizwa kwe-extrusion ngokuyisisekelo kuyibhokisi elimnyama, futhi isimo esingaphakathi asikwazi ukubonwa nhlobo, futhi singaboniswa kuphela ngokusebenzisa izinsimbi. Ngakho-ke, i-instrumentation enembile, ehlakaniphile futhi elula ukuyisebenzisa izosenza siqonde kangcono isimo sayo sangaphakathi, ukuze ukukhiqizwa kufinyelele imiphumela ngokushesha nangcono.

Isikhathi sokuthumela: Mar-01-2023