Ngenxa yezici ze-cpvc impahla eluhlaza, isikulufu, umgqomo, isikhunta se-die, ukudonsa kanye nomklamo wokusika uyahluka emugqeni we-upvc extrusion wepayipi.

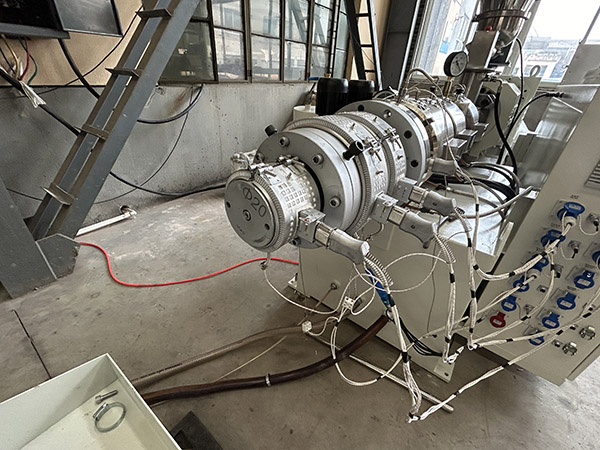

Namuhla ake sigxile ekwakhiweni kwesikulufu kanye nesikhunta se-die.

Ungawushintsha kanjani ukwakheka kwesikulufu se-cpvc pipe extrusion

Ukushintsha idizayini yesikulufu ye-CPVC extrusion yamapayipi kuhlanganisa ukulungiswa ukuze kuthuthukiswe ukuncibilika, ukuxubana, nokudlulisa impahla ye-CPVC. Nazi ezinye izinto ezicatshangelwayo zokushintsha idizayini yesikulufu:

1. **I-Screw Geometry**:

- Lungisa ukujula kwendiza nephimbo: Ukulungisa ukujula kwendiza kanye nephimbo kungathuthukisa ukudlulisa nokuxubana kwezinto ze-CPVC ngaphakathi kwesiteshi sesikulufu.

2. **I-Compression Ratio**:

- Khulisa isilinganiso sokucindezela: I-viscosity ephezulu ye-CPVC yokuncibilika ingase idinge izilinganiso zokucindezela eziphezulu ukuze kukhiqizwe ingcindezi eyanele kanye nokugunda ukuze kuncibilike futhi kuxutshwe.

3. **I-Screw Material and Coating**:

- Sebenzisa izinto ezisetshenziswayo noma izimbotshana ezinokumelana okuthuthukisiwe nokugqwala ukuze umelane nemvelo yokugwaza nokugqwala yokucubungula kwe-CPVC.

- Cabangela ama-coatings noma ukwelashwa okunciphisa ukungqubuzana futhi kuthuthukise izici zokukhululwa ukuze kuthuthukiswe ukugeleza kwe-CPVC okuncibilika futhi kunciphise ukuguga kwezikulufu.

4. **Ukupholisa isikulufa/Ukushisa**:

- Sebenzisa izindawo zokushisisa/zokupholisa eduze kwe-screw barrel ukuze ulawule izinga lokushisa elincibilikayo kanye ne-viscosity, ikakhulukazi ezindaweni lapho i-CPVC ingase ibe nokuwohloka kokushisa noma ukushisisa ngokweqile.

5. **Ukupholisa Isikulufu**:

- Qinisekisa ukupholisa isikulufu esifanele ukuze ugcine ukulawulwa kwezinga lokushisa futhi uvimbele ukushisisa ngokweqile kwe-CPVC encibilikayo, ikakhulukazi ezinqubweni ze-extrusion zesivinini esikhulu.

Ngokucabangela lezi zici nokwenza izinguquko ezifanele kumklamo wesikulufu, abakhiqizi bangakwazi ukuthuthukisa izinqubo zokukhipha amapayipi e-CPVC ukuze bathole ikhwalithi yokuncibilika engaguquki, i-homogeneity, kanye nokuphumayo.

Ungawushintsha kanjani umklamo wokufa we-cpvc pipe extrusion

Ukushintsha idizayini ye-die ye-CPVC extrusion yamapayipi kuhlanganisa ukulungiswa ukuze kuhambisane ne-viscosity ephezulu yokuncibilika kwe-CPVC kanye nokuqinisekisa ukukhishwa okufanayo.

1. **I-Die Heating/Cooling**:

- Lungisa izindawo zokushisisa/zokupholisa: Amazinga okushisa aphezulu okucubungula e-CPVC angase adinge ukuguqulwa kwesistimu yokushisisa/yokupholisa ukuze kugcinwe ukulawulwa kwezinga lokushisa okufanele futhi kuvinjwe ukushisa noma ukupholisa.

2. **Izinto Zokufa Nezingubo Zokunamathela**:

- Cabangela ukusebenzisa izinto/izingubo ezinezingqimba ezinokumelana nokushisa okuphezulu: Amazinga okushisa aphezulu e-CPVC angase adinge izinto ezifayo noma okokunamathela okungamelana namazinga okushisa aphakeme ngaphandle kokuwohloka.

3. **I-Die Surface Qeda**:

- Qinisekisa ukuthi indawo yokufa ebushelelezi nefanayo: Indawo yokufa ebushelelezi isiza ukunciphisa amandla okungqubuzana nokugunda, inciphise ubungozi bokuncibilika kokuqhekeka nokuqinisekisa ukukhishwa okufanayo.

4. **Amadivayisi okulawula ukugeleza**:

- Hlanganisa amadivaysi okulawula ukugeleza, njengezinto ezifakiwe noma imikhawulo, ukuze kuthuthukiswe ukusatshalaliswa kokugeleza kanye nokufana kwengcindezi kuyo yonke iphrofayela ye-die, ikakhulukazi kuma-die geometries ayinkimbinkimbi.

5. **I-Die Design Simulation**:

- Sebenzisa isoftware yokulingisa idizayini ukuze uhlaziye ukuziphatha kokugeleza, ukusatshalaliswa kwengcindezi, namaphrofayili okushisa ngaphakathi kwefayizi. Lokhu kuvumela ukuhlolwa okubonakalayo kwezinguquko ezihlukahlukene ze-die ukuze kuthuthukiswe ukusebenza ngaphambi kokusetshenziswa ngokomzimba.

Ngokucabangela lezi zici nokwenza izinguquko ezifanele kumklamo wokufa, abakhiqizi bangakwazi ukuthuthukisa izinqubo zokukhipha amapayipi e-CPVC ukuze bathole ikhwalithi engaguquki nokunemba kobukhulu.

Enqubweni ye-extrusion yepayipi ye-cpvc, amaphuzu okufanele aqaphele

Ngesikhathi senqubo yokukhishwa kwamapayipi e-CPVC (Chlorinated Polyvinyl Chloride), amaphuzu amaningana adinga ukunakwa ngokucophelela ukuze kuqinisekiswe ukukhiqizwa kwamapayipi ekhwalithi ephezulu. Nawa amaphuzu abalulekile:

1. **Ukuphatha Izinto kanye Nokuxuba**:

- Qinisekisa ukuphathwa ngendlela efanele kanye nokuxutshwa kwenhlaka ye-CPVC nezithasiselo ukuze kuzuzwe ukuhlakazeka okufanayo nokungaguquguquki kokubalulekile. Ukuxuba okufanele kubalulekile ekugcineni izakhiwo ezifiselekayo zekhompiyutha ye-CPVC.

2. **Ukulawula izinga lokushisa**:

- Qapha futhi ulawule izinga lokushisa le-extrusion ngokucophelela, njengoba impahla ye-CPVC inezidingo ezithile zokushisa zokucutshungulwa. Gcina izinga lokushisa ngaphakathi kwebanga elinconyiwe ukuze uvimbele ukuwohloka kwezinto futhi uqinisekise ukugeleza kokuncibilika okufanele.

3. **Idizayini yesikulufu nokucushwa**:

- Sebenzisa izikulufu ze-extruder eziklanyelwe ngqo ukucubungula impahla ye-CPVC. Idizayini yesikulufu kufanele inikeze ukuxutshwa okwanele kanye ne-homogenization yokuncibilika kuyilapho inciphisa ukushisisa kwe-shear ukuze kugwenywe ukuwohloka kwezinto.

4. **I-Die Design and Calibration**:

- Qinisekisa ukuthi idizayini ye-die ifanele ukukhishwa kwepayipi le-CPVC, enobukhulu obufanele kanye nejometri ukuze kukhiqizwe amapayipi anogqinsi olungaguquki odongeni nobubanzi. Linganisa idayizi kahle ukuze ufinyelele ubukhulu bepayipi elifanayo.

5. **Ukupholisa nokucisha**:

- Sebenzisa izinhlelo ezisebenzayo zokupholisa nokucisha ukuze upholise ngokushesha ipayipi le-CPVC elikhishwe futhi usethe ubukhulu balo. Ukupholisa okufanele kubalulekile ekuvimbeleni ukugoqa noma ukuhlanekezelwa kwepayipi nokuqinisekisa ukuzinza kwe-dimensional.

6. **Ukudonsa kanye Nokulinganisa**:

- Lawula isivinini sokudonsa kanye nosayizi wepayipi le-CPVC ukuze ufinyelele ubukhulu obufunekayo kanye nokuqedwa kwendawo. Ukudonsa nokulinganisa ngendlela efanele kuqinisekisa ukufana kobubanzi bepayipi nokuqina kodonga kubo bonke ubude bepayipi.

7. **Ukuqapha Nokulawula Ikhwalithi**:

- Sebenzisa uhlelo olubanzi lokuqapha nokulawula ikhwalithi ukuze kutholwe noma yikuphi ukukhubazeka noma ukungahambisani kumapayipi e-CPVC akhishiwe. Yenza ukuhlola nokuhlola okuvamile ukuze uqinisekise ukuthotshelwa kwemininingwane namazinga.

Ngokuphatha ngokucophelela lawa maphuzu phakathi nenqubo yokukhipha, abakhiqizi bangakhiqiza amapayipi ekhwalithi ephezulu e-CPVC ahlangabezana nezicaciso ezidingekayo kanye namazinga okusebenza.

Isikhathi sokuthumela: Apr-02-2024