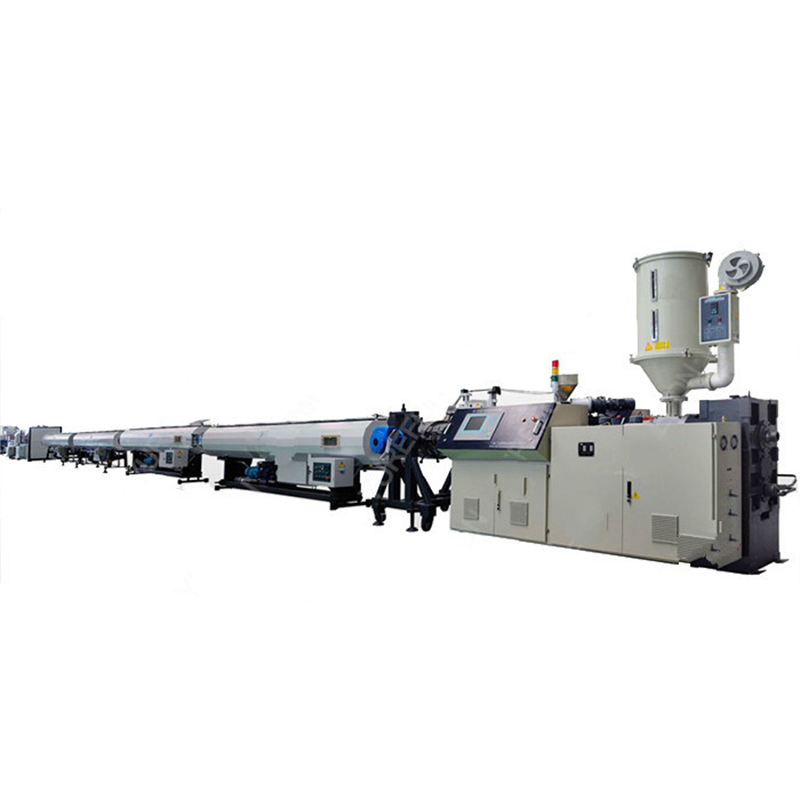

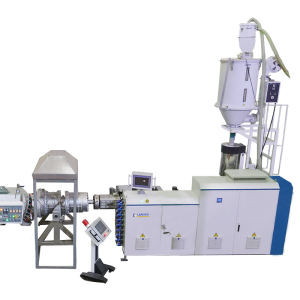

I-LB-PP-R/PE-RT Umugqa Wokukhiqiza Ipayipi

Isiphakeli sezinto ezibonakalayo—i-screw extruder eyodwa—isikhunta kanye ne-calibrator—umshini wokwenza ivacuum— umshini wokupholisa wokufutha—umshini wokudonsa—iyunithi yokusika engena-swarfless—stacker.

Isivinini esikhulu sokukhiqiza singaba ngu-35m/min (isisekelo samapayipi angu-20mm).

Ngezidingo ezahlukene, ulayini wokukhiqiza ungase usetshenziselwe ukwenza amapayipi anobubanzi obuhlukene nokuqina kodonga.

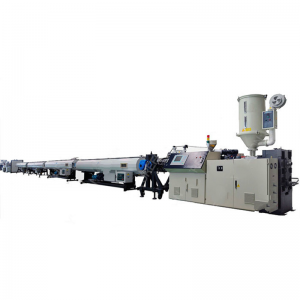

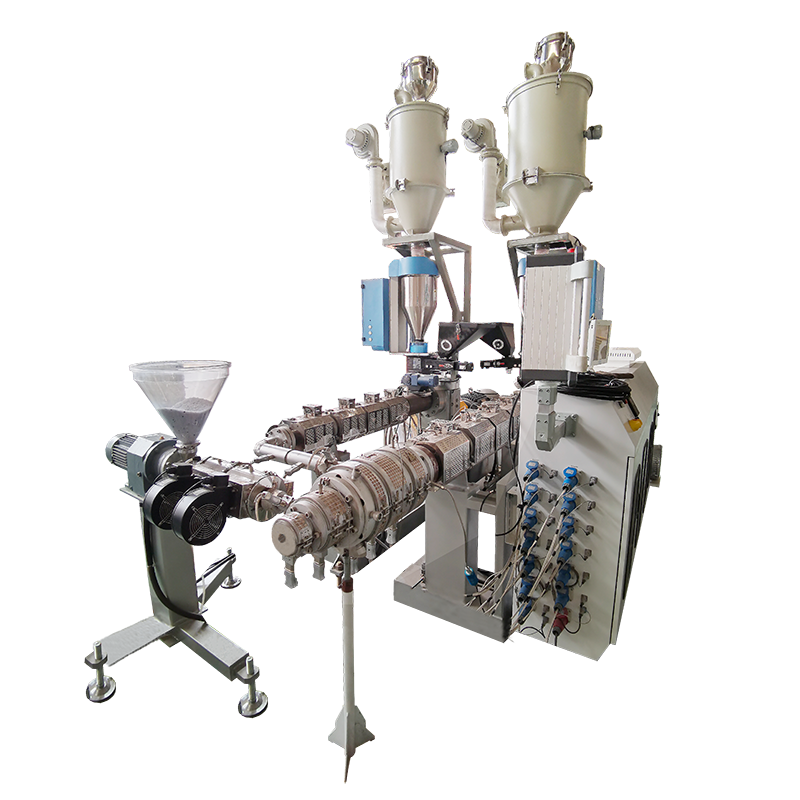

I-extrusion ephindwe kabili noma emine izothuthukisa umthamo wokukhiphayo womugqa Wokukhiqiza we-PP-R.

Ukukhiqizwa kwamapayipi e-PE-RT noma e-PP-R kungenziwa ngokuguqulwa okufanele komshini.

| Imodeli | Ibanga lamapayipi | Isikulufa Imodeli | Amandla emoto | Ubude obuphelele | Okukhiphayo okuphezulu |

| LB-63 | 16-63 mm | SJ65 | 37KW | 22m | 80-120kg |

| I-LB-110 | 20-110 mm | SJ75 | 55KW | 30m | 100-160kg |

| I-LB-160 | 50-160 mm | SJ75 | 90KW | 35m | 120-250kg |

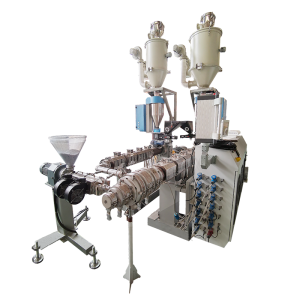

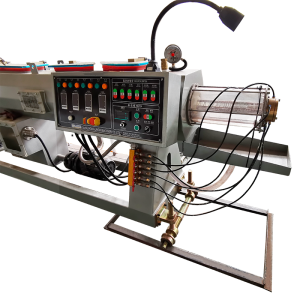

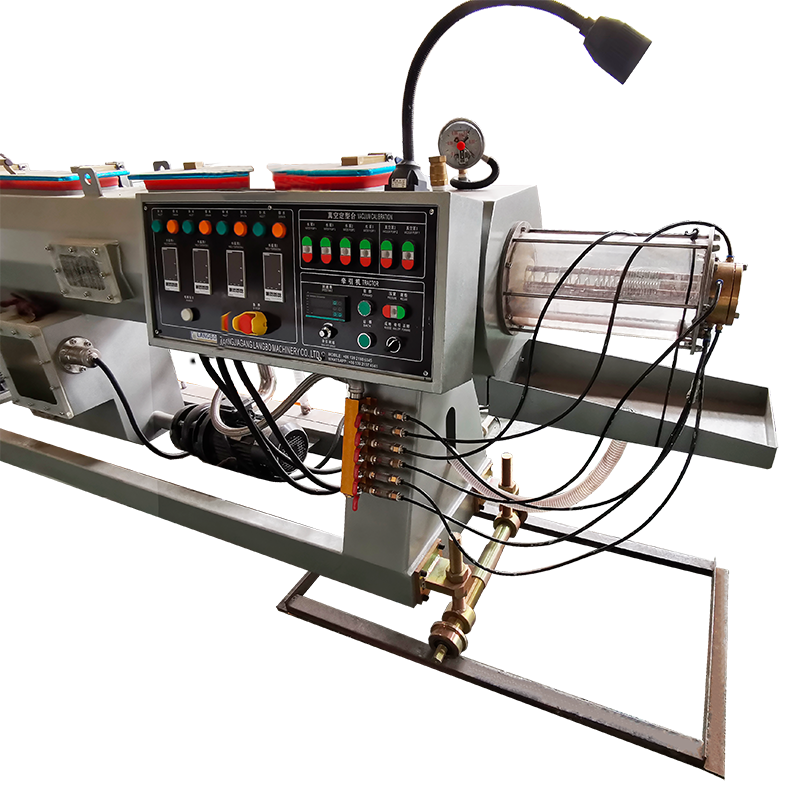

Umshini wokukhipha isikulufa esisodwa

I-extruder yakhiwe ngezici eziphezulu zomkhiqizo ukuze kuqinisekiswe ukuzinza kokukhiqiza, ukusebenza kahle kanye nokuqina komshini. I-extruder yethu yabela isikulufu esisodwa esijwayelekile samazwe ngamazwe kanye nomgqomo. Isikulufu sinokuqina okuqinile okuqinisekisa impilo ende yesevisi kanye nomphumela ohlukile we-plasticizing. Lo mugqa wokukhipha amapayipi usebenzisa ukonga amandla isikulufa esisodwa esinesikhunta esikhethekile, ukusebenza kahle kokukhiqiza kukhuphuke ngo-30%, ukusetshenziswa kwamandla kungaphansi kuka-20%.

Isikhunta

Isikhunta sinomklamo obanzi wesiteshi sokugeleza ukuze kuqinisekiswe umthamo ophezulu wokukhipha kanye nomthelela omuhle wokuncibilika. Yenziwa futhi ihlolwe ngumkhiqizi onolwazi. Ukulawulwa kwezinga lokushisa okuthuthukisiwe kanye nomklamo wesiteshi sokugeleza kuqinisekisa ukulawulwa okunembile kwezinga lokushisa lokuncibilika.

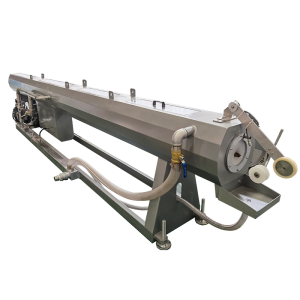

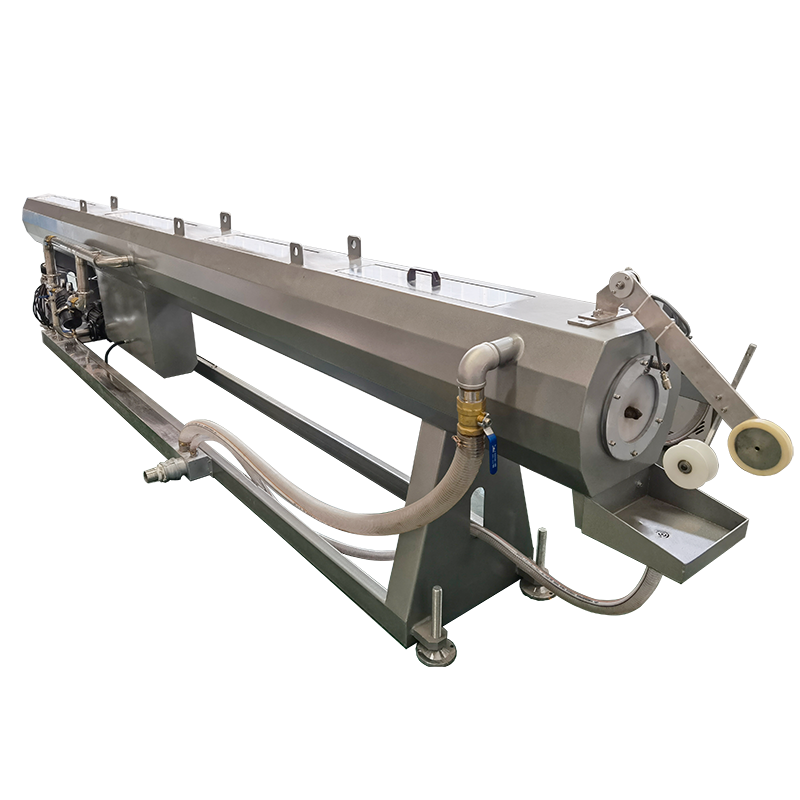

I-Vacuum Tank

Onke amathangi ethu evacuum nawokupholisa akhiwe ngezinto ezingagqwali ezingama-304 ukuvikela ukugqwala. Amathangi ethu e-vacuum alawulwa ngedijithali okuvumela inqubo ezenzakalelayo ngokuphelele. Umbambi esinyathelweni sokuqala sethangi lokulinganisa i-vacuum uqinisekisa ukuma kwepayipi futhi unikeza amandla engeziwe kumapayipi ahambayo.

Ithangi lokupholisa

Ubude obanele bokufutha nokupholisa buzokwenza ngcono ukusebenza kahle kokupholisa. Isistimu yokulawula izinga lokushisa lamanzi ngokuzenzakalelayo ilungiswa ngokuya ngokuzwa kwezinga lokushisa.

Iyunithi yokuthutha

Isibungu esithathu emshinini wokudonsa siqinisekisa ukuthi amapayipi akhiqiziwe asebenza ngokuzinzile futhi azinzile. Sisebenzisa indlela eyingqayizivele yokuvimbela ukuqanda kwamapayipi kuyilapho idizayini yethu eyingqayizivele yebhande iqinisekisa ukudonsa okufanele ngaphandle kokushelela. Umshini wethu wokudonsa amapayipi uqhutshwa yi-servo motor ukuze ande

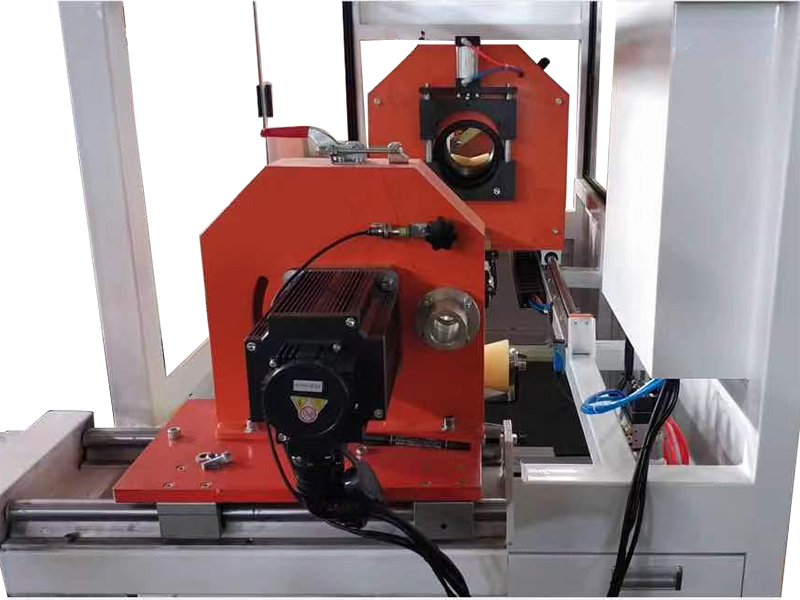

Umsiki osheshayo

Sihlinzeka nge-cutter esheshayo yomugqa wokukhiqiza we-PP-R njengoba isivinini sokukhipha ipayipi siyashesha. Ulayini wokukhiqiza we-PP-R unesistimu yokulawula ye-PLC ehlakaniphile. Ingakwazi ukusika ngobude obuqondile ithola imikhiqizo yobukhulu obumisiwe.