I-LB-Double Strand PVC Pipe Extrusion Line

I-Raw Material—i-mixer—i-conical twin screw extruder—isikhunta kanye ne-calibrator—umshini wokwenza i-vacuum—umshini wokupholisa wokufutha—umshini wokudonsa—iyunithi yokusika—umshini wokubethela—isitaki.

| Imodeli | 50B | 50C | 63B |

| Ibanga lamapayipi (mm) | 16-50 | 16-50 | 16-63 |

| Isikulufa Imodeli | 51/105 | 65/132 | 65/132 |

| Ukukhipha (kg) | 200 | 250 | 280 |

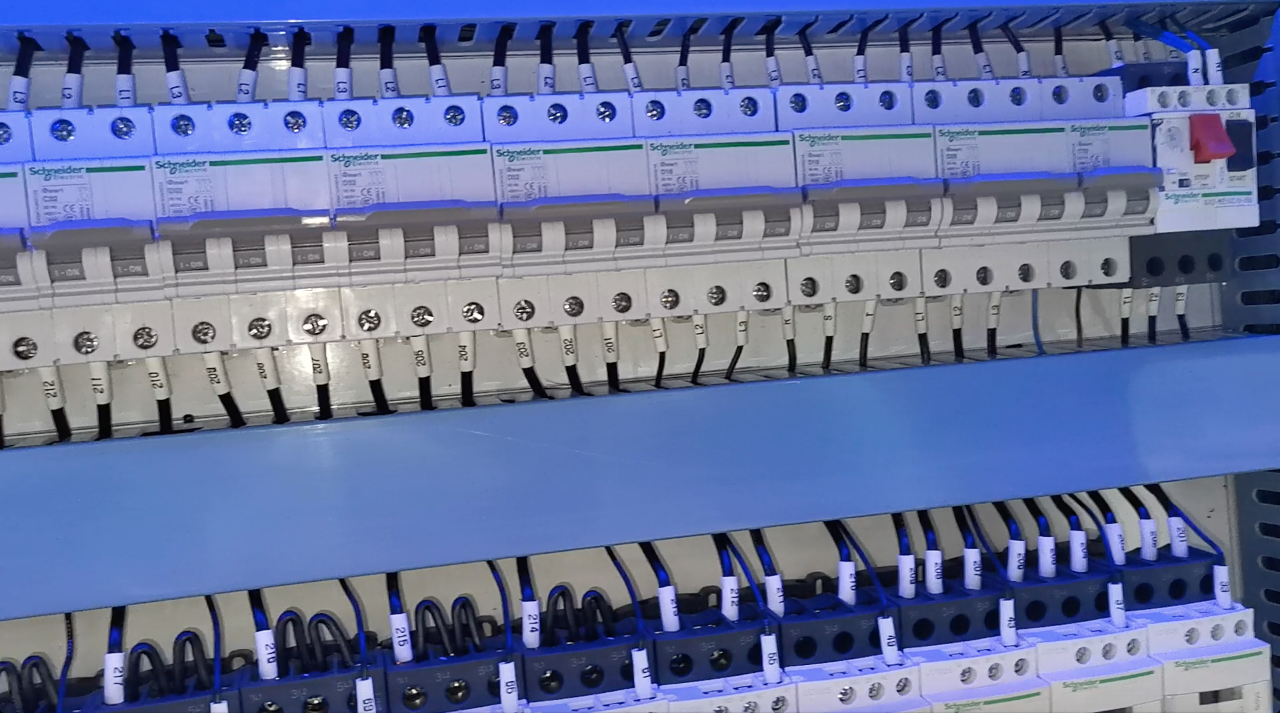

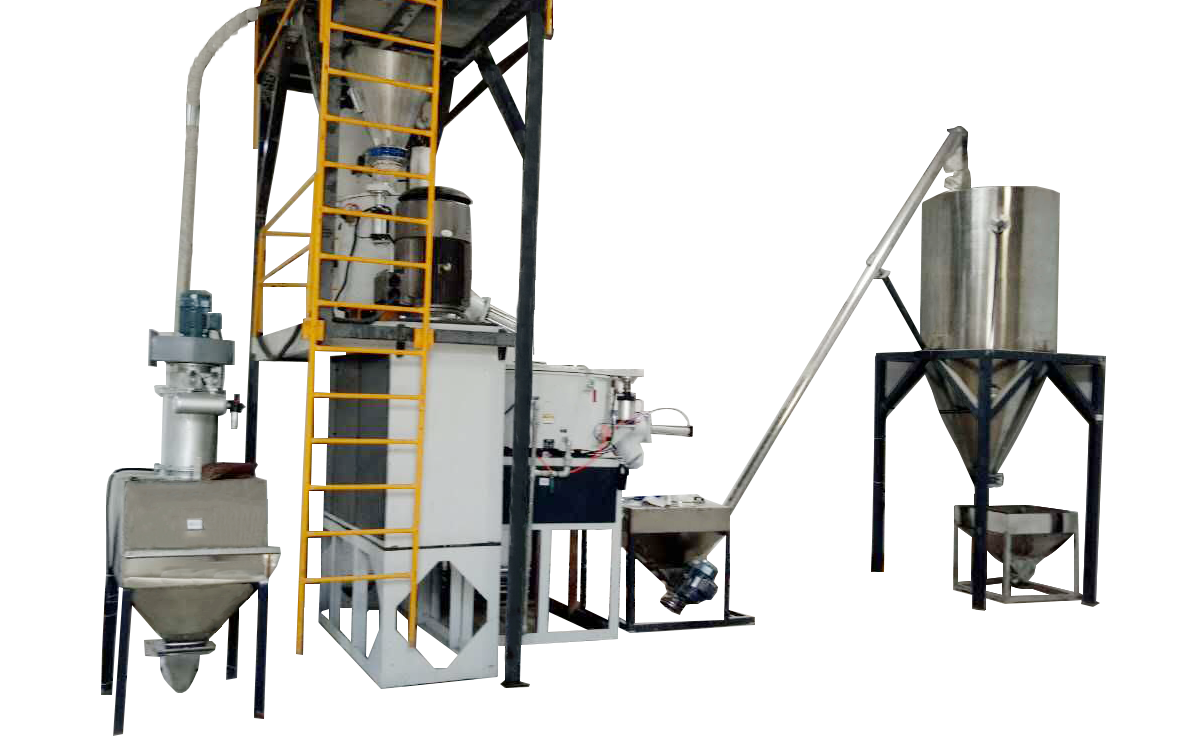

Umdidiyeli

Idizayini elungiselelwe ngonjiniyela abanolwazi

I-self-friction njengomthombo wokushisa, ukusebenza kahle kwamandla njengomphumela

Ukulayishwa kwe-vaccum yomsindo ophansi nesimo sokusebenza esingenalo uthuli

Ukulayishwa kokuvunguza ngemuva kokuxuba ukugcina ukwakheka kwengxube

Ukushisisa okuzenzakalelayo nokulayisha kabusha

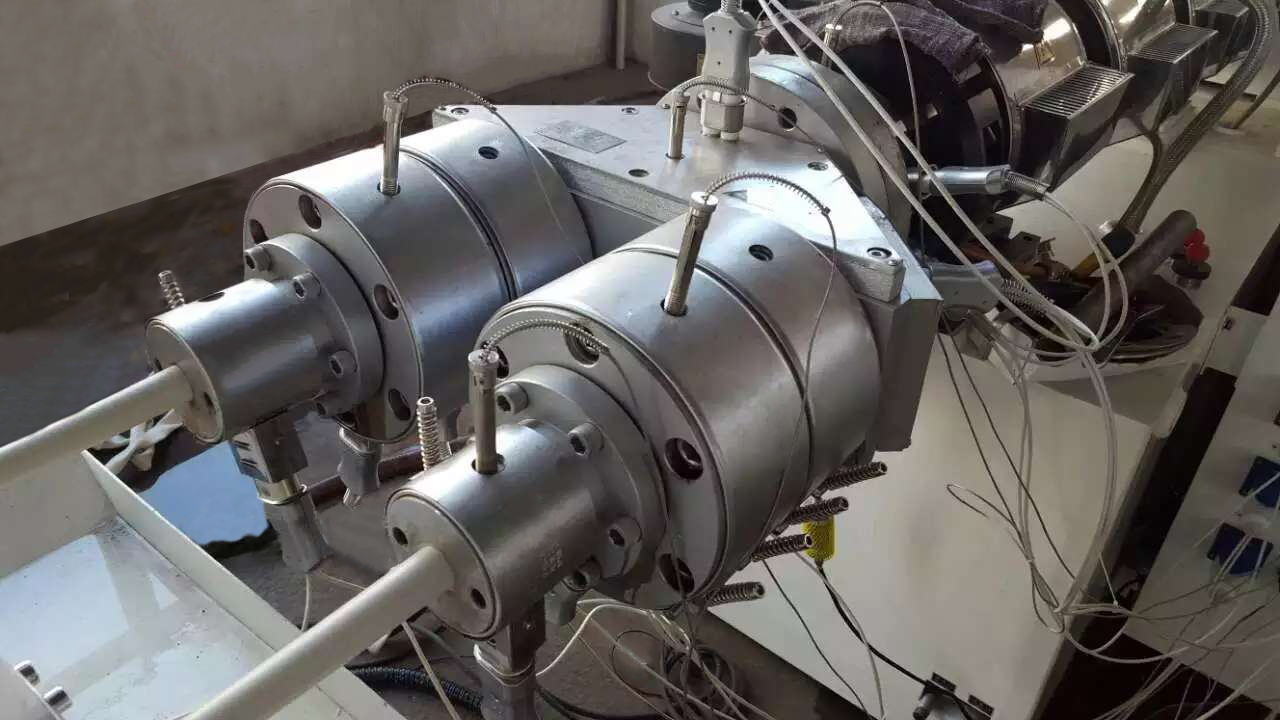

I-Conical Twin Screw Extruder

Idizayini ekhethekile yokucubungula kahle kwe-PVC powder

unomphela uzibuthe we-synchronous motor yokunciphisa ukusetshenziswa kwamandla okungaba ngu-10% uma kuqhathaniswa ne-DC noma i-AC Motor.

I-logic yokusebenza eqondiswe ku-opharetha ukuze isebenze ngokukhalipha futhi kulula ngesikhathi sokukhiqiza

Isikrini sokuthinta (ongakukhetha) sokuphathwa kolwazi oludidiyelwe nokusebenza okulula

Isikhunta

Idizayinelwe ngokukhethekile isiteshi sokugeleza sokubunjwa kwepayipi okuhle kakhulu kanye nengcindezi yokuncibilika enengqondo.

Isilinganiso esikhulu sokucindezela siqinisekisa umphumela omuhle kakhulu we-plasticizing.

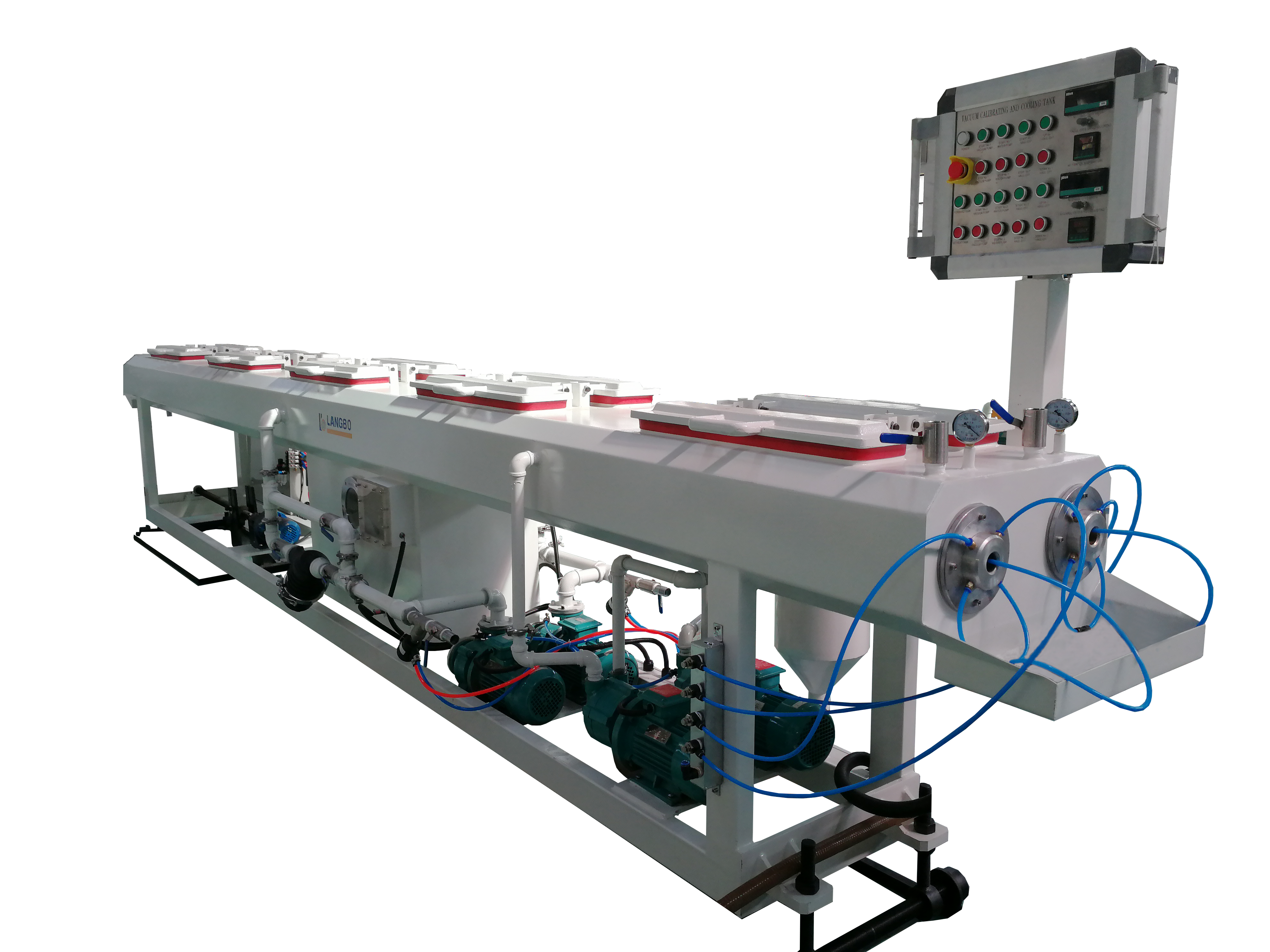

Ukulinganisa kweVacuum & Ukupholisa

Isistimu yokupholisa ngokwehlukana ye-double strand enesistimu yamaphampu ezimele.

isistimu yokulawula i-vacuum yokuguqulwa kwemvamisa yendawo ehlala njalo ye-vacuum esebenzisa amandla aphansi kakhulu.

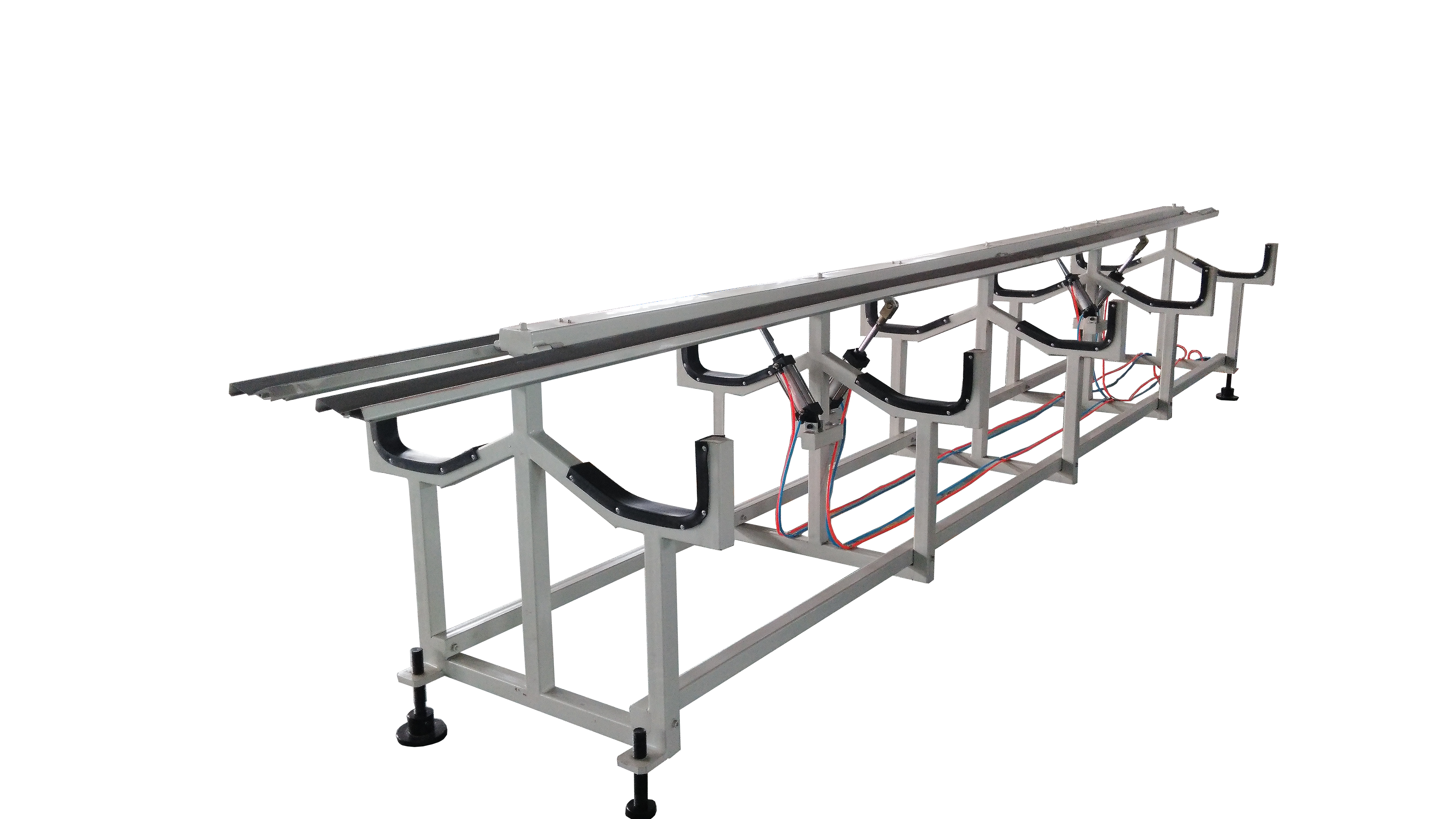

Inhlanganisela ye-Haul-off & cutter

I-Servo Motor kanye nesinciphisi sekhwalithi ephezulu sokunyakaza okuvumelanisiwe kwebhande noma isibungu

Umqondo wokuhudula owenziwe ngendlela oyifisayo wamukelwe ngokusekelwe kumfuneko ethile yokukhiqiza

Umqondo wokusika ofanelekayo osuselwe kwimfuneko yokukhiqiza

isifaki khodi sokunemba okuphezulu siqinisekisa ubude bokusika obunemba futhi obuzinzile

Ukuhlanganiswa kokukhipha nokusika kuyakhethwa ngenzuzo yokonga isikhala.

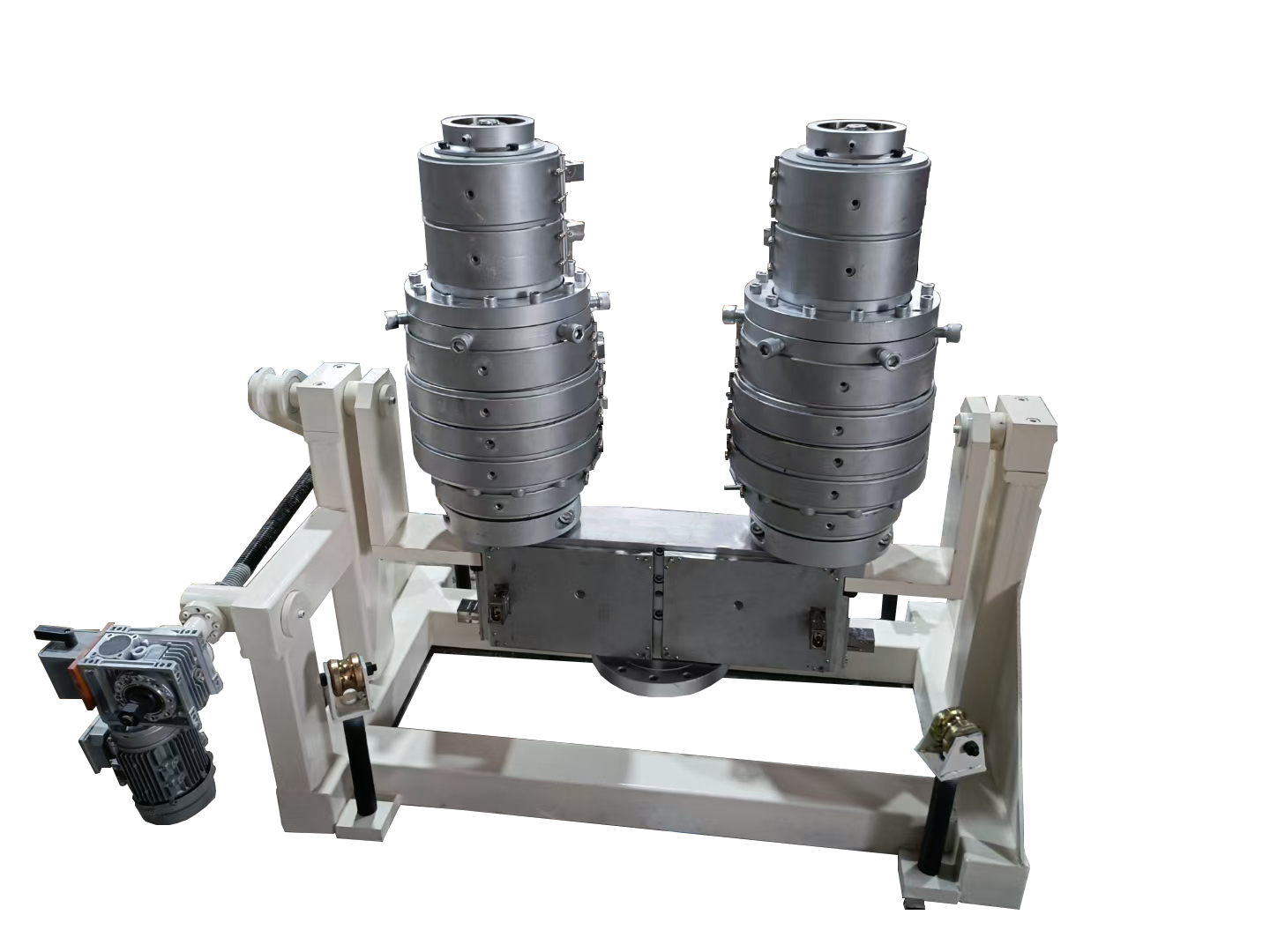

Belling

Indawo yokushisa emibili yokushaya ngesikhathi ngesivinini somugqa

Ukonga amandla ngokushintsha okuzenzakalelayo kwesici sokushisisa

Umqondo wokupholisa owenziwe ngezifiso ngokusekelwe kumfuneko yokukhiqiza

Isitaki Somoya

Isakhiwo sesitaki esizinzile kanye ne-pneumatic eshayelwa ukulayishwa kabusha kwamapayipi

Ukuhambisa isenzo kulawulwa uhlelo lwe-PLC

Isilawuli esihlukene sakho kokubili i-extrusion strand